Page 308 - Challenges in Corrosion Costs Causes Consequences and Control(2015)

P. 308

286 CORROSION CONTROL AND PREVENTION

Coatings such as modified epoxies, coal-tar epoxy, or solvent-borne epoxy have

been used by many shipbuilders since 1998. The problem with these coatings is that

the lifetime of these coatings is such that they can give protection for only 8–10 years,

which is less than the design life of the vessels. These coatings are not resistant to the

temperatures in double-hulled tankers and the bacteria that causes pitting corrosion

on the bottom of tanks. The use of solvent-free epoxy on the top and bottom of a

crude tanker should prevent corrosion of the tanker.

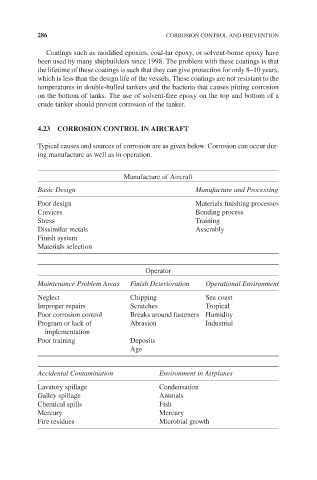

4.23 CORROSION CONTROL IN AIRCRAFT

Typical causes and sources of corrosion are as given below. Corrosion can occur dur-

ing manufacture as well as in operation.

Manufacture of Aircraft

Basic Design Manufacture and Processing

Poor design Materials finishing processes

Crevices Bonding process

Stress Training

Dissimilar metals Assembly

Finish system

Materials selection

Operator

Maintenance Problem Areas Finish Deterioration Operational Environment

Neglect Chipping Sea coast

Improper repairs Scratches Tropical

Poor corrosion control Breaks around fasteners Humidity

Program or lack of Abrasion Industrial

implementation

Poor training Deposits

Age

Accidental Contamination Environment in Airplanes

Lavatory spillage Condensation

Galley spillage Animals

Chemical spills Fish

Mercury Mercury

Fire residues Microbial growth