Page 404 - Challenges in Corrosion Costs Causes Consequences and Control(2015)

P. 404

382 CONSEQUENCES OF CORROSION

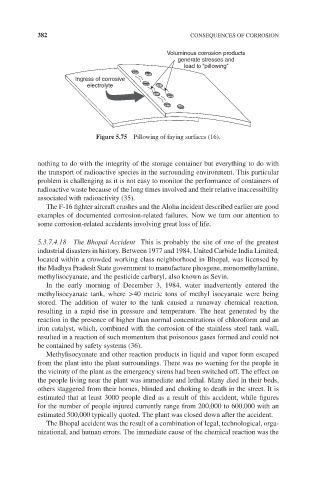

Voluminous corrosion products

generate stresses and

lead to “pillowing”

Ingress of corrosive

electrolyte

Figure 5.75 Pillowing of faying surfaces (16).

nothing to do with the integrity of the storage container but everything to do with

the transport of radioactive species in the surrounding environment. This particular

problem is challenging as it is not easy to monitor the performance of containers of

radioactive waste because of the long times involved and their relative inaccessibility

associated with radioactivity (35).

The F-16 fighter aircraft crashes and the Aloha incident described earlier are good

examples of documented corrosion-related failures. Now we turn our attention to

some corrosion-related accidents involving great loss of life.

5.3.7.4.18 The Bhopal Accident This is probably the site of one of the greatest

industrial disasters in history. Between 1977 and 1984, United Carbide India Limited,

located within a crowded working class neighborhood in Bhopal, was licensed by

the Madhya Pradesh State government to manufacture phosgene, monomethylamine,

methylisocyanate, and the pesticide carbaryl, also known as Sevin.

In the early morning of December 3, 1984, water inadvertently entered the

methylisocyanate tank, where >40 metric tons of methyl isocyanate were being

stored. The addition of water to the tank caused a runaway chemical reaction,

resulting in a rapid rise in pressure and temperature. The heat generated by the

reaction in the presence of higher than normal concentrations of chloroform and an

iron catalyst, which, combined with the corrosion of the stainless steel tank wall,

resulted in a reaction of such momentum that poisonous gases formed and could not

be contained by safety systems (36).

Methylisocyanate and other reaction products in liquid and vapor form escaped

from the plant into the plant surroundings. There was no warning for the people in

the vicinity of the plant as the emergency sirens had been switched off. The effect on

the people living near the plant was immediate and lethal. Many died in their beds,

others staggered from their homes, blinded and choking to death in the street. It is

estimated that at least 3000 people died as a result of this accident, while figures

for the number of people injured currently range from 200,000 to 600,000 with an

estimated 500,000 typically quoted. The plant was closed down after the accident.

The Bhopal accident was the result of a combination of legal, technological, orga-

nizational, and human errors. The immediate cause of the chemical reaction was the