Page 411 - Challenges in Corrosion Costs Causes Consequences and Control(2015)

P. 411

AGE-RELIABILITY CHARACTERISTICS 389

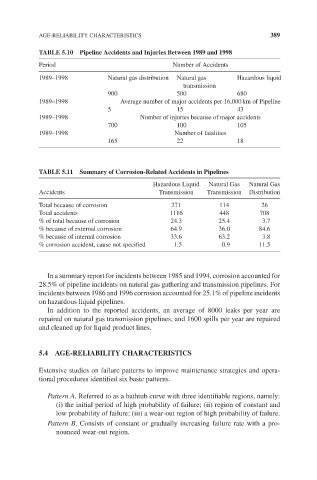

TABLE 5.10 Pipeline Accidents and Injuries Between 1989 and 1998

Period Number of Accidents

1989–1998 Natural gas distribution Natural gas Hazardous liquid

transmission

900 500 680

1989–1998 Average number of major accidents per 16,000 km of Pipeline

5 15 43

1989–1998 Number of injuries because of major accidents

700 100 105

1989–1998 Number of fatalities

165 22 18

TABLE 5.11 Summary of Corrosion-Related Accidents in Pipelines

Hazardous Liquid Natural Gas Natural Gas

Accidents Transmission Transmission Distribution

Total because of corrosion 271 114 26

Total accidents 1116 448 708

% of total because of corrosion 24.3 25.4 3.7

% because of external corrosion 64.9 36.0 84.6

% because of internal corrosion 33.6 63.2 3.8

% corrosion accident, cause not specified 1.5 0.9 11.5

In a summary report for incidents between 1985 and 1994, corrosion accounted for

28.5% of pipeline incidents on natural gas gathering and transmission pipelines. For

incidents between 1986 and 1996 corrosion accounted for 25.1% of pipeline incidents

on hazardous liquid pipelines.

In addition to the reported accidents, an average of 8000 leaks per year are

repaired on natural gas transmission pipelines, and 1600 spills per year are repaired

and cleaned up for liquid product lines.

5.4 AGE-RELIABILITY CHARACTERISTICS

Extensive studies on failure patterns to improve maintenance strategies and opera-

tional procedures identified six basic patterns.

Pattern A. Referred to as a bathtub curve with three identifiable regions, namely:

(i) the initial period of high probability of failure; (ii) region of constant and

low probability of failure; (iii) a wear-out region of high probability of failure.

Pattern B. Consists of constant or gradually increasing failure rate with a pro-

nounced wear-out region.