Page 217 - Chemical and process design handbook

P. 217

Speight_Part II_C 11/7/01 3:08 PM Page 2.157

CEMENT 2.157

Clay

Limestone

Crusher Dryer Slurry tank

Cement

clinker

Cement Kiln

Sodium sulfate

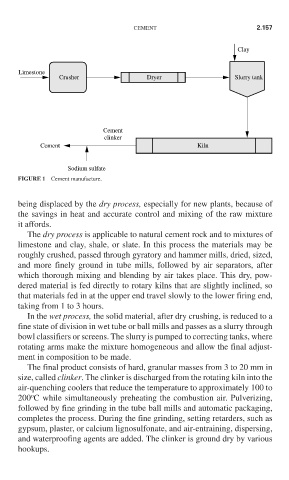

FIGURE 1 Cement manufacture.

being displaced by the dry process, especially for new plants, because of

the savings in heat and accurate control and mixing of the raw mixture

it affords.

The dry process is applicable to natural cement rock and to mixtures of

limestone and clay, shale, or slate. In this process the materials may be

roughly crushed, passed through gyratory and hammer mills, dried, sized,

and more finely ground in tube mills, followed by air separators, after

which thorough mixing and blending by air takes place. This dry, pow-

dered material is fed directly to rotary kilns that are slightly inclined, so

that materials fed in at the upper end travel slowly to the lower firing end,

taking from 1 to 3 hours.

In the wet process, the solid material, after dry crushing, is reduced to a

fine state of division in wet tube or ball mills and passes as a slurry through

bowl classifiers or screens. The slurry is pumped to correcting tanks, where

rotating arms make the mixture homogeneous and allow the final adjust-

ment in composition to be made.

The final product consists of hard, granular masses from 3 to 20 mm in

size, called clinker. The clinker is discharged from the rotating kiln into the

air-quenching coolers that reduce the temperature to approximately 100 to

o

200 C while simultaneously preheating the combustion air. Pulverizing,

followed by fine grinding in the tube ball mills and automatic packaging,

completes the process. During the fine grinding, setting retarders, such as

gypsum, plaster, or calcium lignosulfonate, and air-entraining, dispersing,

and waterproofing agents are added. The clinker is ground dry by various

hookups.