Page 63 - Chemical and process design handbook

P. 63

Speight_Part II_A 11/7/01 3:16 PM Page 2.4

2.4 MANUFACTURE OF CHEMICALS

form, but the catalytic species has been shown to be a mercuric ion com-

plex. The excess acetylene sweeps out the dissolved acetaldehyde, which

is condensed by water and refrigerated brine and then scrubbed with water;

this crude acetaldehyde is purified by distillation; the unreacted acetylene

is recycled. The catalytic mercuric ion is reduced to catalytically inactive

mercurous sulfate (Hg SO ) and metallic mercury. Sludge, consisting of

2

4

reduced catalyst and tars, is drained from the reactor at intervals and resul-

fated. The rate of catalyst depletion can be reduced by adding ferric or

other suitable ions to the reaction solution. These ions reoxidize the mer-

curous ion to the mercuric ion; consequently, the quantity of sludge that

must be recovered is reduced.

In one variation of the process, acetylene is completely hydrated with

o

water in a single operation at 68 to 73 C using the mercuric-iron salt cata-

lyst. The acetaldehyde is partially removed by vacuum distillation and the

mother liquor recycled to the reactor. The aldehyde vapors are cooled to

o

about 35 C, compressed to 37 psi (253 kPa), and condensed. It is claimed

that this combination of vacuum and pressure operations substantially

reduces heating and refrigeration costs.

The commercial process of choice for acetaldehyde production is the

direct oxidation of ethylene.

CH =CH + [O] → CH CH=O

2 2 3

There are two variations for this commercial production route: the

two-stage process and the one-stage process.

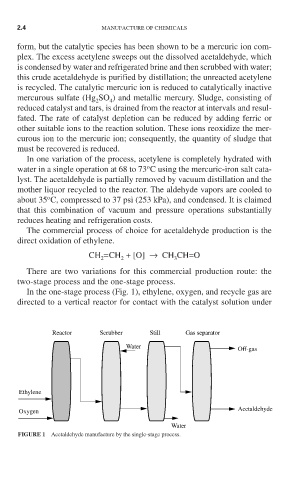

In the one-stage process (Fig. 1), ethylene, oxygen, and recycle gas are

directed to a vertical reactor for contact with the catalyst solution under

Reactor Scrubber Still Gas separator

Water

Off-gas

Ethylene

Oxygen Acetaldehyde

Water

FIGURE 1 Acetaldehyde manufacture by the single-stage process.