Page 64 - Chemical and process design handbook

P. 64

Speight_Part II_A 11/7/01 3:16 PM Page 2.5

ACETALDEHYDE 2.5

Reactor Reactor Still Gas separator Still

Waste gas

Air

Acetaldehyde

Ethylene

Steam

Air

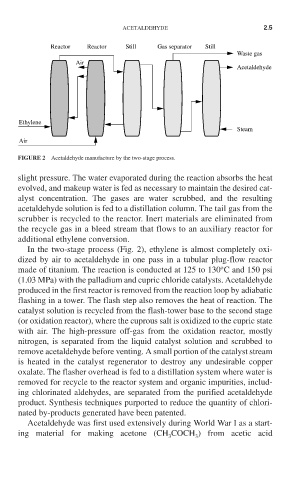

FIGURE 2 Acetaldehyde manufacture by the two-stage process.

slight pressure. The water evaporated during the reaction absorbs the heat

evolved, and makeup water is fed as necessary to maintain the desired cat-

alyst concentration. The gases are water scrubbed, and the resulting

acetaldehyde solution is fed to a distillation column. The tail gas from the

scrubber is recycled to the reactor. Inert materials are eliminated from

the recycle gas in a bleed stream that flows to an auxiliary reactor for

additional ethylene conversion.

In the two-stage process (Fig. 2), ethylene is almost completely oxi-

dized by air to acetaldehyde in one pass in a tubular plug-flow reactor

o

made of titanium. The reaction is conducted at 125 to 130 C and 150 psi

(1.03 MPa) with the palladium and cupric chloride catalysts. Acetaldehyde

produced in the first reactor is removed from the reaction loop by adiabatic

flashing in a tower. The flash step also removes the heat of reaction. The

catalyst solution is recycled from the flash-tower base to the second stage

(or oxidation reactor), where the cuprous salt is oxidized to the cupric state

with air. The high-pressure off-gas from the oxidation reactor, mostly

nitrogen, is separated from the liquid catalyst solution and scrubbed to

remove acetaldehyde before venting. A small portion of the catalyst stream

is heated in the catalyst regenerator to destroy any undesirable copper

oxalate. The flasher overhead is fed to a distillation system where water is

removed for recycle to the reactor system and organic impurities, includ-

ing chlorinated aldehydes, are separated from the purified acetaldehyde

product. Synthesis techniques purported to reduce the quantity of chlori-

nated by-products generated have been patented.

Acetaldehyde was first used extensively during World War I as a start-

ing material for making acetone (CH COCH ) from acetic acid

3

3