Page 71 - Chemical and process design handbook

P. 71

Speight_Part II_A 11/7/01 3:16 PM Page 2.12

2.12 MANUFACTURE OF CHEMICALS

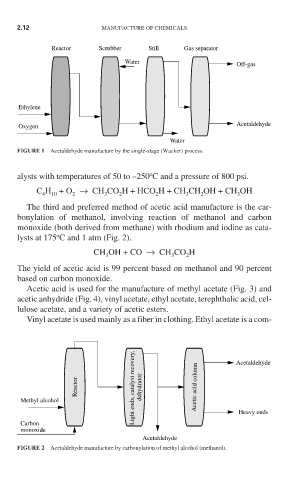

Reactor Scrubber Still Gas separator

Water

Off-gas

Ethylene

Acetaldehyde

Oxygen

Water

FIGURE 1 Acetaldehyde manufacture by the single-stage (Wacker) process.

o

alysts with temperatures of 50 to –250 C and a pressure of 800 psi.

C H + O → CH CO H + HCO H + CH CH OH + CH OH

4 10 2 3 2 2 3 2 3

The third and preferred method of acetic acid manufacture is the car-

bonylation of methanol, involving reaction of methanol and carbon

monoxide (both derived from methane) with rhodium and iodine as cata-

o

lysts at 175 C and 1 atm (Fig. 2).

CH OH + CO → CH CO H

3 3 2

The yield of acetic acid is 99 percent based on methanol and 90 percent

based on carbon monoxide.

Acetic acid is used for the manufacture of methyl acetate (Fig. 3) and

acetic anhydride (Fig. 4), vinyl acetate, ethyl acetate, terephthalic acid, cel-

lulose acetate, and a variety of acetic esters.

Vinyl acetate is used mainly as a fiber in clothing. Ethyl acetate is a com-

Light ends, catalyst recovery, dehydrator Acetic acid column

Reactor Acetaldehyde

Methyl alcohol

Carbon Heavy ends

monoxide

Acetaldehyde

FIGURE 2 Acetaldehyde manufacture by carbonylation of methyl alcohol (methanol).