Page 84 - Chemical and process design handbook

P. 84

Speight_Part II_A 11/7/01 3:16 PM Page 2.25

ACRYLIC ACID

o

o

Acrylic acid (CH =CHCO H, melting point: 13.5 C, boiling point: 141 C,

2 2

o

density: 1.045, flash point: 68 C) and acrylates were once prepared by

reaction of acetylene and carbon monoxide with water or an alcohol, with

nickel carbonyl as catalyst.

HC≡CH + CO + H O → CH =CHCO H

2 2 2

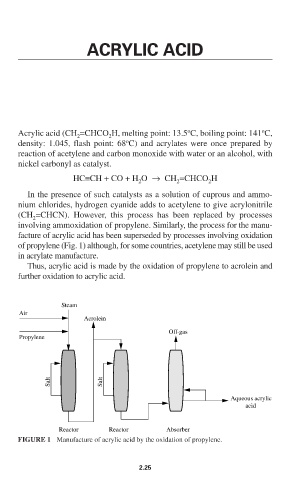

In the presence of such catalysts as a solution of cuprous and ammo-

nium chlorides, hydrogen cyanide adds to acetylene to give acrylonitrile

(CH =CHCN). However, this process has been replaced by processes

2

involving ammoxidation of propylene. Similarly, the process for the manu-

facture of acrylic acid has been superseded by processes involving oxidation

of propylene (Fig. 1) although, for some countries, acetylene may still be used

in acrylate manufacture.

Thus, acrylic acid is made by the oxidation of propylene to acrolein and

further oxidation to acrylic acid.

Steam

Air

Acrolein

Off-gas

Propylene

Salt Salt

Aqueous acrylic

acid

Reactor Reactor Absorber

FIGURE 1 Manufacture of acrylic acid by the oxidation of propylene.

2.25