Page 239 - Chemical engineering design

P. 239

PIPING AND INSTRUMENTATION 215

Retaining

screw O-rings

Seal

face

Spring Rotating

seal

Static

seal

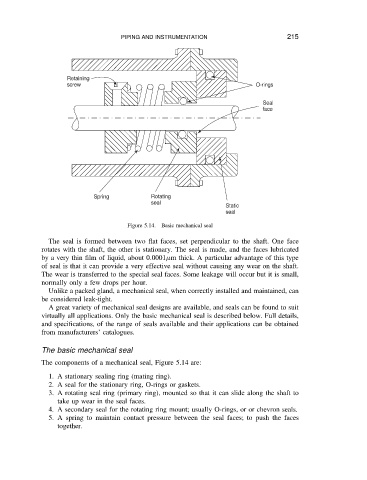

Figure 5.14. Basic mechanical seal

The seal is formed between two flat faces, set perpendicular to the shaft. One face

rotates with the shaft, the other is stationary. The seal is made, and the faces lubricated

by a very thin film of liquid, about 0.0001 m thick. A particular advantage of this type

of seal is that it can provide a very effective seal without causing any wear on the shaft.

The wear is transferred to the special seal faces. Some leakage will occur but it is small,

normally only a few drops per hour.

Unlike a packed gland, a mechanical seal, when correctly installed and maintained, can

be considered leak-tight.

A great variety of mechanical seal designs are available, and seals can be found to suit

virtually all applications. Only the basic mechanical seal is described below. Full details,

and specifications, of the range of seals available and their applications can be obtained

from manufacturers’ catalogues.

The basic mechanical seal

The components of a mechanical seal, Figure 5.14 are:

1. A stationary sealing ring (mating ring).

2. A seal for the stationary ring, O-rings or gaskets.

3. A rotating seal ring (primary ring), mounted so that it can slide along the shaft to

take up wear in the seal faces.

4. A secondary seal for the rotating ring mount; usually O-rings, or or chevron seals.

5. A spring to maintain contact pressure between the seal faces; to push the faces

together.