Page 260 - Chemical engineering design

P. 260

236

CHEMICAL ENGINEERING

The basic components of an automatic trip system are:

1. A sensor to monitor the control variable and provide an output signal when a preset

value is exceeded (the instrument).

2. A link to transfer the signal to the actuator, usually consisting of a system of

pneumatic or electric relays.

3. An actuator to carry out the required action; close or open a valve, switch off a

motor.

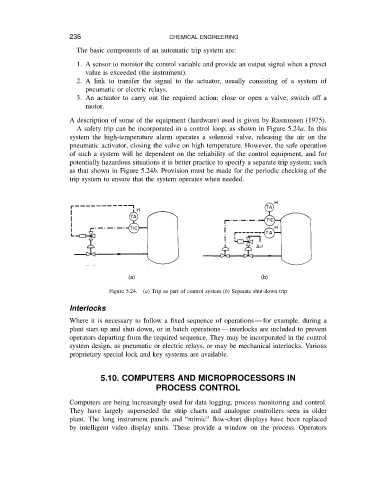

A description of some of the equipment (hardware) used is given by Rasmussen (1975).

A safety trip can be incorporated in a control loop; as shown in Figure 5.24a.Inthis

system the high-temperature alarm operates a solenoid valve, releasing the air on the

pneumatic activator, closing the valve on high temperature. However, the safe operation

of such a system will be dependent on the reliability of the control equipment, and for

potentially hazardous situations it is better practice to specify a separate trip system; such

as that shown in Figure 5.24b. Provision must be made for the periodic checking of the

trip system to ensure that the system operates when needed.

(a) (b)

Figure 5.24. (a) Trip as part of control system (b) Separate shut-down trip

Interlocks

Where it is necessary to follow a fixed sequence of operations for example, during a

plant start-up and shut-down, or in batch operations interlocks are included to prevent

operators departing from the required sequence. They may be incorporated in the control

system design, as pneumatic or electric relays, or may be mechanical interlocks. Various

proprietary special lock and key systems are available.

5.10. COMPUTERS AND MICROPROCESSORS IN

PROCESS CONTROL

Computers are being increasingly used for data logging, process monitoring and control.

They have largely superseded the strip charts and analogue controllers seen in older

plant. The long instrument panels and “mimic” flow-chart displays have been replaced

by intelligent video display units. These provide a window on the process. Operators