Page 319 - Chemical engineering design

P. 319

294

CHEMICAL ENGINEERING

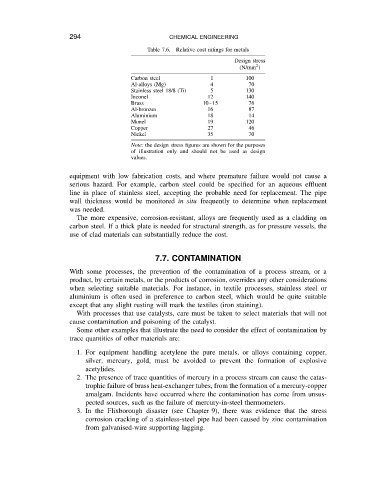

Relative cost ratings for metals

Table 7.6.

Design stress

2

(N/mm )

Carbon steel 1 100

Al-alloys (Mg) 4 70

Stainless steel 18/8 (Ti) 5 130

Inconel 12 140

Brass 10 15 76

Al-bronzes 16 87

Aluminium 18 14

Monel 19 120

Copper 27 46

Nickel 35 70

Note: the design stress figures are shown for the purposes

of illustration only and should not be used as design

values.

equipment with low fabrication costs, and where premature failure would not cause a

serious hazard. For example, carbon steel could be specified for an aqueous effluent

line in place of stainless steel, accepting the probable need for replacement. The pipe

wall thickness would be monitored in situ frequently to determine when replacement

was needed.

The more expensive, corrosion-resistant, alloys are frequently used as a cladding on

carbon steel. If a thick plate is needed for structural strength, as for pressure vessels, the

use of clad materials can substantially reduce the cost.

7.7. CONTAMINATION

With some processes, the prevention of the contamination of a process stream, or a

product, by certain metals, or the products of corrosion, overrides any other considerations

when selecting suitable materials. For instance, in textile processes, stainless steel or

aluminium is often used in preference to carbon steel, which would be quite suitable

except that any slight rusting will mark the textiles (iron staining).

With processes that use catalysts, care must be taken to select materials that will not

cause contamination and poisoning of the catalyst.

Some other examples that illustrate the need to consider the effect of contamination by

trace quantities of other materials are:

1. For equipment handling acetylene the pure metals, or alloys containing copper,

silver, mercury, gold, must be avoided to prevent the formation of explosive

acetylides.

2. The presence of trace quantities of mercury in a process stream can cause the catas-

trophic failure of brass heat-exchanger tubes, from the formation of a mercury-copper

amalgam. Incidents have occurred where the contamination has come from unsus-

pected sources, such as the failure of mercury-in-steel thermometers.

3. In the Flixborough disaster (see Chapter 9), there was evidence that the stress

corrosion cracking of a stainless-steel pipe had been caused by zinc contamination

from galvanised-wire supporting lagging.