Page 322 - Chemical engineering design

P. 322

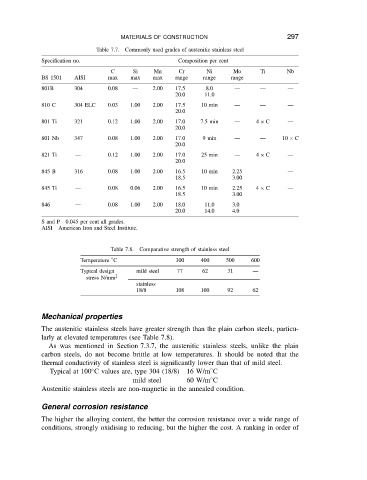

Commonly used grades of austenitic stainless steel

Composition per cent

Specification no. Table 7.7. MATERIALS OF CONSTRUCTION 297

C Si Mn Cr Ni Mo Ti Nb

BS 1501 AISI max max max range range range

801B 304 0.08 2.00 17.5 8.0

20.0 11.0

810 C 304 ELC 0.03 1.00 2.00 17.5 10 min

20.0

801 Ti 321 0.12 1.00 2.00 17.0 7.5 min 4 ð C

20.0

801 Nb 347 0.08 1.00 2.00 17.0 9 min 10 ð C

20.0

821 Ti 0.12 1.00 2.00 17.0 25 min 4 ð C

20.0

845 B 316 0.08 1.00 2.00 16.5 10 min 2.25

18.5 3.00

845 Ti 0.08 0.06 2.00 16.5 10 min 2.25 4 ð C

18.5 3.00

846 0.08 1.00 2.00 18.0 11.0 3.0

20.0 14.0 4.0

S and P 0.045 per cent all grades.

AISI American Iron and Steel Institute.

Table 7.8. Comparative strength of stainless steel

Temperature ° C 300 400 500 600

Typical design mild steel 77 62 31

stress N/mm 2

stainless

18/8 108 100 92 62

Mechanical properties

The austenitic stainless steels have greater strength than the plain carbon steels, particu-

larly at elevated temperatures (see Table 7.8).

As was mentioned in Section 7.3.7, the austenitic stainless steels, unlike the plain

carbon steels, do not become brittle at low temperatures. It should be noted that the

thermal conductivity of stainless steel is significantly lower than that of mild steel.

Ž

Ž

Typical at 100 C values are, type 304 (18/8) 16 W/m C

Ž

mild steel 60 W/m C

Austenitic stainless steels are non-magnetic in the annealed condition.

General corrosion resistance

The higher the alloying content, the better the corrosion resistance over a wide range of

conditions, strongly oxidising to reducing, but the higher the cost. A ranking in order of