Page 391 - Chemical engineering design

P. 391

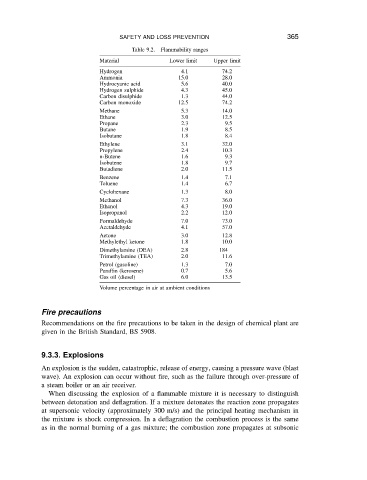

Table 9.2.

Flammability ranges

Material SAFETY AND LOSS PREVENTION Upper limit 365

Lower limit

Hydrogen 4.1 74.2

Ammonia 15.0 28.0

Hydrocyanic acid 5.6 40.0

Hydrogen sulphide 4.3 45.0

Carbon disulphide 1.3 44.0

Carbon monoxide 12.5 74.2

Methane 5.3 14.0

Ethane 3.0 12.5

Propane 2.3 9.5

Butane 1.9 8.5

Isobutane 1.8 8.4

Ethylene 3.1 32.0

Propylene 2.4 10.3

n-Butene 1.6 9.3

Isobutene 1.8 9.7

Butadiene 2.0 11.5

Benzene 1.4 7.1

Toluene 1.4 6.7

Cyclohexane 1.3 8.0

Methanol 7.3 36.0

Ethanol 4.3 19.0

Isopropanol 2.2 12.0

Formaldehyde 7.0 73.0

Acetaldehyde 4.1 57.0

Aetone 3.0 12.8

Methylethyl ketone 1.8 10.0

Dimethylamine (DEA) 2.8 184

Trimethylamine (TEA) 2.0 11.6

Petrol (gasoline) 1.3 7.0

Paraffin (kerosene) 0.7 5.6

Gas oil (diesel) 6.0 13.5

Volume percentage in air at ambient conditions

Fire precautions

Recommendations on the fire precautions to be taken in the design of chemical plant are

given in the British Standard, BS 5908.

9.3.3. Explosions

An explosion is the sudden, catastrophic, release of energy, causing a pressure wave (blast

wave). An explosion can occur without fire, such as the failure through over-pressure of

a steam boiler or an air receiver.

When discussing the explosion of a flammable mixture it is necessary to distinguish

between detonation and deflagration. If a mixture detonates the reaction zone propagates

at supersonic velocity (approximately 300 m/s) and the principal heating mechanism in

the mixture is shock compression. In a deflagration the combustion process is the same

as in the normal burning of a gas mixture; the combustion zone propagates at subsonic