Page 142 - Chemical process engineering design and economics

P. 142

126 Chapter 3

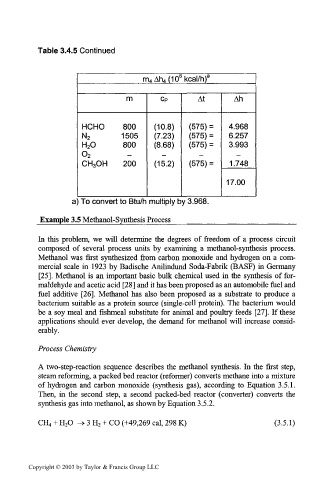

Table 3.4.5 Continued

6

m 4Ah 4(10 kcal/h) a

m CP At Ah

HCHO 800 (10.8) (575) = 4.968

(7.23)

N 2 1505 (575) = 6.257

H 2O 800 (8.68) (575) = 3.993

0 2

CH 3OH 200 (15.2) (575) = 1.748

17.00

a) To convert to Btu/h multiply by 3.968.

Example 3.5 Methanol-Synthesis Process______________________

In this problem, we will determine the degrees of freedom of a process circuit

composed of several process units by examining a methanol-synthesis process.

Methanol was first synthesized from carbon monoxide and hydrogen on a com-

mercial scale in 1923 by Badische Anilindund Soda-Fabrik (BASF) in Germany

[25]. Methanol is an important basic bulk chemical used in the synthesis of for-

maldehyde and acetic acid [28] and it has been proposed as an automobile fuel and

fuel additive [26]. Methanol has also been proposed as a substrate to produce a

bacterium suitable as a protein source (single-cell protein). The bacterium would

be a soy meal and fishmeal substitute for animal and poultry feeds [27]. If these

applications should ever develop, the demand for methanol will increase consid-

erably.

Process Chemistry

A two-step-reaction sequence describes the methanol synthesis. In the first step,

steam reforming, a packed bed reactor (reformer) converts methane into a mixture

of hydrogen and carbon monoxide (synthesis gas), according to Equation 3.5.1.

Then, in the second step, a second packed-bed reactor (converter) converts the

synthesis gas into methanol, as shown by Equation 3.5.2.

CH 4 + H 2O -> 3 H 2 + CO (+49,269 cal, 298 K) (3.5.1)

Copyright © 2003 by Taylor & Francis Group LLC