Page 165 - Chemical process engineering design and economics

P. 165

148 Chapter 4

requires specifying a tube length, diameter, and layout. Although this detail will

eventually be needed, at the preliminary stage of a process design we are only

interested in an approximate estimate of the cost. Kern [1] gives detailed heat-

exchanger design procedures, which, according to Frank [29], are too conserva-

tive. Some up-to-date procedures can be found in Reference 15 and in the engi-

neering literature.

Heat-Transfer Fluids

Before selecting a heat-transfer fluid, examine the process for any possibility of

interchanging heat between process streams to conserve energy. Frequently, one

process stream needs to be heated and another process stream cooled. After this

possibility has been exhausted, select a heat-transfer fluid to cool or heat the proc-

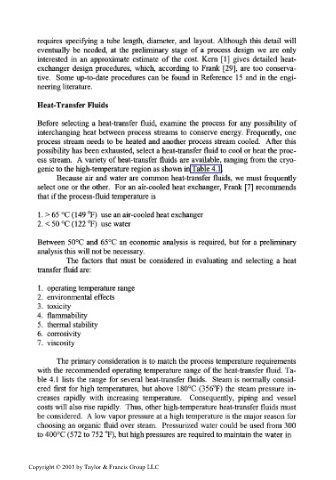

ess stream. A variety of heat-transfer fluids are available, ranging from the cryo-

genic to the high-temperature region as shown in Table 4.1.

Because air and water are common heat-transfer fluids, we must frequently

select one or the other. For an air-cooled heat exchanger, Frank [7] recommends

that if the process-fluid temperature is

1. > 65 °C (149 °F) use an air-cooled heat exchanger

2.<50°C(122°F) use water

Between 50°C and 65°C an economic analysis is required, but for a preliminary

analysis this will not be necessary.

The factors that must be considered in evaluating and selecting a heat

transfer fluid are:

1. operating temperature range

2. environmental effects

3. toxicity

4. flammability

5. thermal stability

6. corrosivity

7. viscosity

The primary consideration is to match the process temperature requirements

with the recommended operating temperature range of the heat-transfer fluid. Ta-

ble 4.1 lists the range for several heat-transfer fluids. Steam is normally consid-

ered first for high temperatures, but above 180°C (356°F) the steam pressure in-

creases rapidly with increasing temperature. Consequently, piping and vessel

costs will also rise rapidly. Thus, other high-temperature heat-transfer fluids must

be considered. A low vapor pressure at a high temperature is the major reason for

choosing an organic fluid over steam. Pressurized water could be used from 300

to 400°C (572 to 752 °F), but high pressures are required to maintain the water in

Copyright © 2003 by Taylor & Francis Group LLC