Page 243 - Chemical process engineering design and economics

P. 243

224 Chapter 5

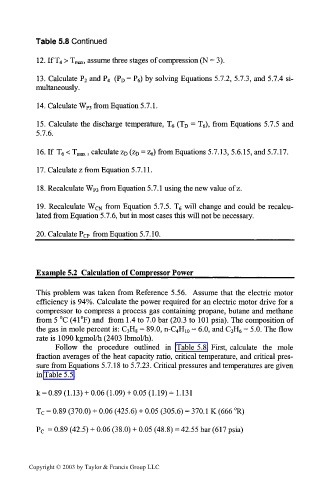

Table 5.8 Continued

12. If T 4 > T^, assume three stages of compression (N = 3).

13. Calculate P 2 and P 4 (P D= P 6) by solving Equations 5.7.2, 5.7.3, and 5.7.4 si-

multaneously.

14. Calculate W P3 from Equation 5.7.1.

15. Calculate the discharge temperature, T 6 (T D = T 6), from Equations 5.7.5 and

5.7.6.

16. If T 6 < Tmax, calculate Z D (Z D = z 6) from Equations 5.7.13, 5.6.15, and 5.7.17.

17. Calculate z from Equation 5.7.11.

18. Recalculate W P3 from Equation 5.7.1 using the new value of z.

19. Recalculate W CN from Equation 5.7.5. T 6 will change and could be recalcu-

lated from Equation 5.7.6, but in most cases this will not be necessary.

20. Calculate PCP from Equation 5.7.10.

Example 5.2 Calculation of Compressor Power_________________

This problem was taken from Reference 5.56. Assume that the electric motor

efficiency is 94%. Calculate the power required for an electric motor drive for a

compressor to compress a process gas containing propane, butane and methane

from 5 °C (41°F) and from 1.4 to 7.0 bar (20.3 to 101 psia). The composition of

the gas in mole percent is: C 3H 8 = 89.0, n-C 4Hi 0 = 6.0, and C 2H 6 = 5.0. The flow

rate is 1090 kgmol/h (2403 Ibmol/h).

Follow the procedure outlined in Table 5.8. First, calculate the mole

fraction averages of the heat capacity ratio, critical temperature, and critical pres-

sure from Equations 5.7.18 to 5.7.23. Critical pressures and temperatures are given

in Table 5.5.

k = 0.89 (1.13) + 0.06 (1.09) + 0.05 (1.19) = 1.131

T c = 0.89 (370.0) + 0.06 (425.6) + 0.05 (305.6) = 370.1 K (666 °R)

PC = 0.89 (42.5) + 0.06 (38.0) + 0.05 (48.8) = 42.55 bar (617 psia)

Copyright © 2003 by Taylor & Francis Group LLC