Page 387 - Chemical process engineering design and economics

P. 387

Reactor Design 367

The next consideration is classifying reactors according to the phases in con-

tact. These are:

1. gas-liquid

2. liquid-liquid

3. gas-solid

4. liquid-solid

5. gas-liquid-solid

After specifying the energy form, the catalyst and the phases in contact, the

next task is to decide whether to conduct the reaction in a batch or continuous

mode. In the batch mode, the reactants are charged to a stirred-tank reactor (STR)

and allowed to react for a specified time. After completing the reaction, the reac-

tor is emptied to obtain the products. This operating mode is unsteady state.

Other unsteady-state reactors are: (1) continuous addition of one or more of the

reactants with no product withdrawal, and (2) all the reactants added at the begin-

ning with continuous withdrawal of product. At steady-state, reactants flow into

and products flow out continuously without a change in concentration and tem-

perature in the reactor.

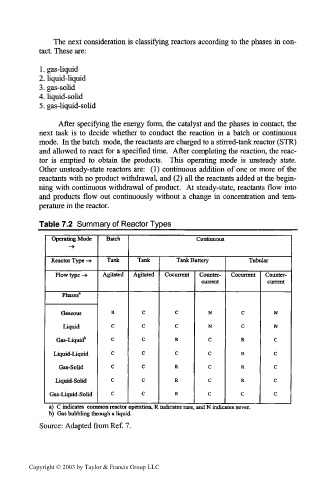

Table 7.2 Summary of Reactor Types

Operating Mode Batch Continuous

— »

Reactor Type -» Tank Tank Tank Battery Tubular

Flow type -» Agitated Agitated Cocurrent Counter- Cocurrent Counter-

current current

Phases'

Gaseous R C C N C N

Liquid C C C N C N

1

Gas-Liquid " C C R C R C

Liquid-Liquid C C C C R C

Gas-Solid C C R C R C

Liquid-Solid C C R C R C

Gas-Liquid-Solid C C R C C C

a) C indicates common reactor operation, R indicates rare, and N indicates never.

b) Gas bubbling through a liquid.

Source: Adapted from Ref. 7.

Copyright © 2003 by Taylor & Francis Group LLC