Page 393 - Chemical process engineering design and economics

P. 393

Reactor Design 373

Table 7.5 gives the calculation procedure. Any reaction kinetics, indicated by

Equation 7.4.4, can be used in the procedure. For each reactor in the series, we

assume

1. perfect mixing

2. constant volume

3. constant temperature

4. constant density

5. constant heat capacities

6. equal mixer power for each reactor

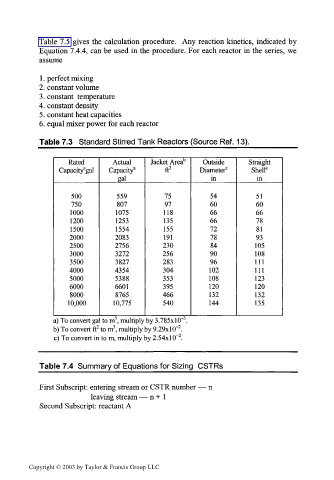

Table 7.3 Standard Stirred Tank Reactors (Source Ref. 13).

Rated Actual Jacket Area b Outside Straight

Capacitygal Capacity 3 ft 2 Diameter 0 Shell c

gal in in

500 559 75 54 51

750 807 97 60 60

1000 1075 118 66 66

1200 1253 135 66 78

1500 1554 155 72 81

2000 2083 191 78 93

2500 2756 230 84 105

3000 3272 256 90 108

3500 3827 283 96 111

4000 4354 304 102 111

5000 5388 353 108 123

6000 6601 395 120 120

8000 8765 466 132 132

10,000 10,775 540 144 135

3

a) To convert gal to m , multiply by 3.785x10

2

2

3

b) To convert ft to m , multiply by 9.29xlO" .

2

c) To convert in to m, multiply by 2.54xlO" .

Table 7.4 Summary of Equations for Sizing CSTRs

First Subscript: entering stream or CSTR number — n

leaving stream — n + 1

Second Subscript: reactant A

Copyright © 2003 by Taylor & Francis Group LLC