Page 396 - Chemical process engineering design and economics

P. 396

376 Chapter 7

Table 7.5 Continued

10. Determine if Qc is sufficient from Equation 7.4.14.

11. If not, determine if the jacket + coil area is sufficient.

12. Calculate the jacket plus coil heat-transfer rate, Qj + Q c.

13. Determine if Qj + Qc is sufficient from Equation 7.4.14.

14. If not, then an external heat exchanger is necessary. The area may be estimated

from the approximate method outlined in Chapter 4.

15. Finally, calculate the mixer power, P n, by from Equations 7.4.15 and 7.4.16.

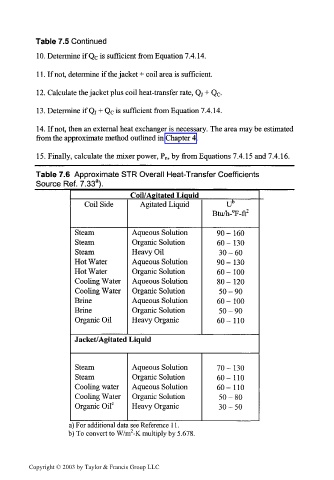

Table 7.6 Approximate STR Overall Heat-Transfer Coefficients

a

Source Ref. 7.33 ).

Coil/Agitated Liquid

Coil Side Agitated Liquid U b

Btu/h-°F-ft 2

Steam Aqueous Solution 90 - 160

Steam Organic Solution 60 - 130

Steam Heavy Oil 30-60

Hot Water Aqueous Solution 90-130

Hot Water Organic Solution 60 - 100

Cooling Water Aqueous Solution 80 - 120

Cooling Water Organic Solution 50-90

Brine Aqueous Solution 60 - 100

Brine Organic Solution 50-90

Organic Oil Heavy Organic 60-110

Jacket/Agitated Liquid

Steam Aqueous Solution 70-130

Steam Organic Solution 60-110

Cooling water Aqueous Solution 60-110

Cooling Water Organic Solution 50-80

Organic Oil c Heavy Organic 30-50

a) For additional data see Reference 11.

2

b) To convert to W/m -K multiply by 5.678.

Copyright © 2003 by Taylor & Francis Group LLC