Page 399 - Chemical process engineering design and economics

P. 399

Reactor Design 379

coolant is chilled water. Size the reactor, determine the heat exchanger type and

area, and calculate the mixer power.

Data

3

3

Methanol volumetric flow rate 800ft /h(22.7m /h)

3

Propylene oxide volumetric flow rate 800 fWh (22.7 m /h)

3

3

Acid solution volumetric flow rate 4000ft /h(l 13 m /h)

Feed inlet temperature 75°F(23.9°C)

Reaction temperature 100°F(37.8°C)

Chilled water inlet temperature 5°C(41°F)

Chilled water exit temperature 15°C(59°F)

Required propylene oxide conversion 0.37

Thermodynamic properties are summarized in Table 7.1.1, and reaction

properties are given below. Fogler [16] estimated the heat capacity for propylene

glycol using a rale-of-thumb. The rule states that the majority of low-molecular-

weight, oxygen-containing organic liquids have a heat capacity of 0.6 cal/g °F

±15%(35Btu/lbmol-°F)

Reaction Properties

Pre-exponential factor, A 16.96 xlO 12 h' 1

Activation energy, E 32,400 Btu/lbmol (75,330 kJ/kgmol)

Follow the calculation procedure outlined in Table 7.5. Using the equations

listed in Table 7.4, first calculate the reaction volume. Then select a standard reac-

tion volume (rated capacity) from Table 7.3. The actual capacity (reactor volume)

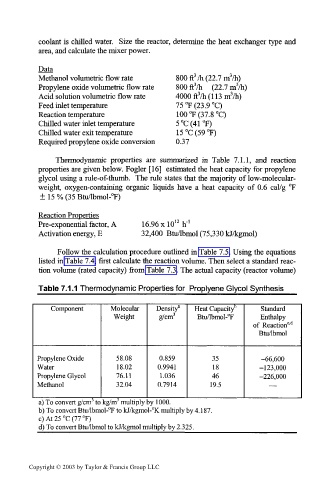

Table 7.1.1 Thermodynamic Properties for Proplyene Glycol Synthesis

Component Molecular Density 3 Heat Capacity 13 Standard

Weight g/cm 3 Btu/lbmol-°F Enthalpy

of Reaction c>d

Btu/lbmol

Propylene Oxide 58.08 0.859 35 -66,600

Water 18.02 0.9941 18 -123,000

Propylene Glycol 76.11 1.036 46 -226,000

Methanol 32.04 0.7914 19.5

a) To convert g/cm to kg/m multiply by 1000.

b) To convert Btu/lbmol-°F to kJ/kgmol-°K multiply by 4.187.

c) At 25 °C (77 °F)

d) To convert Btu/lbmol to kJ/kgmol multiply by 2.325.

Copyright © 2003 by Taylor & Francis Group LLC