Page 128 - Compression Machinery for Oil and Gas

P. 128

Centrifugal Compressors Chapter 3 115

(12,000psig) [25a]. The Petrobras Tupi III project also deserves mention due to

achieving 8120psi (560bar) during compressor test with an extremely high-

density gas [25b]. The Tupi III compressor is said to have the highest discharge

gas density ever achieved in a centrifugal compressor at 556.1kg/m 3

3

(34.72lb m /ft ). Interestingly, all three of these projects were by different

original equipment manufacturers (OEMs).

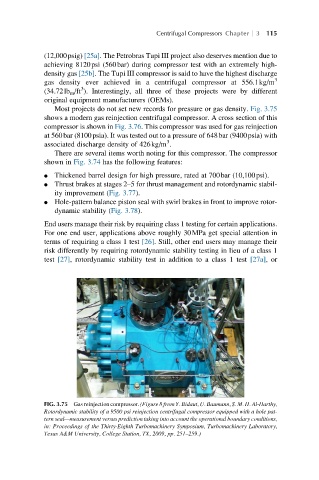

Most projects do not set new records for pressure or gas density. Fig. 3.75

shows a modern gas reinjection centrifugal compressor. A cross section of this

compressor is shown in Fig. 3.76. This compressor was used for gas reinjection

at 560bar (8100psia). It was tested out to a pressure of 648bar (9400psia) with

3

associated discharge density of 426kg/m .

There are several items worth noting for this compressor. The compressor

shown in Fig. 3.74 has the following features:

l Thickened barrel design for high pressure, rated at 700bar (10,100psi).

l Thrust brakes at stages 2–5 for thrust management and rotordynamic stabil-

ity improvement (Fig. 3.77).

l Hole-pattern balance piston seal with swirl brakes in front to improve rotor-

dynamic stability (Fig. 3.78).

End users manage their risk by requiring class 1 testing for certain applications.

For one end user, applications above roughly 30MPa get special attention in

terms of requiring a class 1 test [26]. Still, other end users may manage their

risk differently by requiring rotordynamic stability testing in lieu of a class 1

test [27], rotordynamic stability test in addition to a class 1 test [27a],or

FIG. 3.75 Gas reinjection compressor. (Figure 8 from Y. Bidaut, U. Baumann, S. M. H. Al-Harthy,

Rotordynamic stability of a 9500 psi reinjection centrifugal compressor equipped with a hole pat-

tern seal—measurement versus prediction taking into account the operational boundary conditions,

in: Proceedings of the Thirty-Eighth Turbomachinery Symposium, Turbomachinery Laboratory,

Texas A&M University, College Station, TX, 2009, pp. 251–259.)