Page 133 - Compression Machinery for Oil and Gas

P. 133

120 SECTION II Types of Equipment

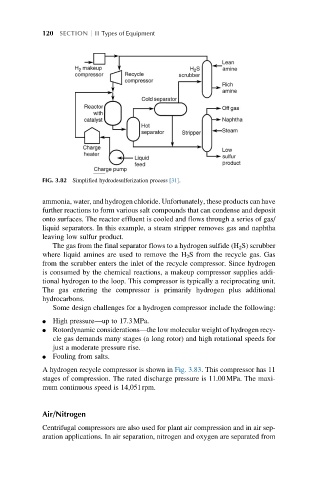

FIG. 3.82 Simplified hydrodesulferization process [31].

ammonia, water, and hydrogen chloride. Unfortunately, these products can have

further reactions to form various salt compounds that can condense and deposit

onto surfaces. The reactor effluent is cooled and flows through a series of gas/

liquid separators. In this example, a steam stripper removes gas and naphtha

leaving low sulfur product.

The gas from the final separator flows to a hydrogen sulfide (H 2 S) scrubber

where liquid amines are used to remove the H 2 S from the recycle gas. Gas

from the scrubber enters the inlet of the recycle compressor. Since hydrogen

is consumed by the chemical reactions, a makeup compressor supplies addi-

tional hydrogen to the loop. This compressor is typically a reciprocating unit.

The gas entering the compressor is primarily hydrogen plus additional

hydrocarbons.

Some design challenges for a hydrogen compressor include the following:

l High pressure—up to 17.3MPa.

l Rotordynamic considerations—the low molecular weight of hydrogen recy-

cle gas demands many stages (a long rotor) and high rotational speeds for

just a moderate pressure rise.

l Fouling from salts.

A hydrogen recycle compressor is shown in Fig. 3.83. This compressor has 11

stages of compression. The rated discharge pressure is 11.00MPa. The maxi-

mum continuous speed is 14,051rpm.

Air/Nitrogen

Centrifugal compressors are also used for plant air compression and in air sep-

aration applications. In air separation, nitrogen and oxygen are separated from