Page 134 - Compression Machinery for Oil and Gas

P. 134

Centrifugal Compressors Chapter 3 121

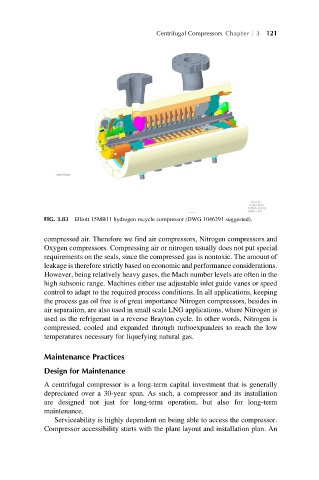

FIG. 3.83 Elliott 15MB11 hydrogen recycle compressor (DWG 1046291 suggested).

compressed air. Therefore we find air compressors, Nitrogen compressors and

Oxygen compressors. Compressing air or nitrogen usually does not put special

requirements on the seals, since the compressed gas is nontoxic. The amount of

leakage is therefore strictly based on economic and performance considerations.

However, being relatively heavy gases, the Mach number levels are often in the

high subsonic range. Machines either use adjustable inlet guide vanes or speed

control to adapt to the required process conditions. In all applications, keeping

the process gas oil free is of great importance Nitrogen compressors, besides in

air separation, are also used in small scale LNG applications, where Nitrogen is

used as the refrigerant in a reverse Brayton cycle. In other words, Nitrogen is

compressed, cooled and expanded through turboexpanders to reach the low

temperatures necessary for liquefying natural gas.

Maintenance Practices

Design for Maintenance

A centrifugal compressor is a long-term capital investment that is generally

depreciated over a 30-year span. As such, a compressor and its installation

are designed not just for long-term operation, but also for long-term

maintenance.

Serviceability is highly dependent on being able to access the compressor.

Compressor accessibility starts with the plant layout and installation plan. An