Page 226 - Compression Machinery for Oil and Gas

P. 226

Reciprocating Compressors Chapter 5 215

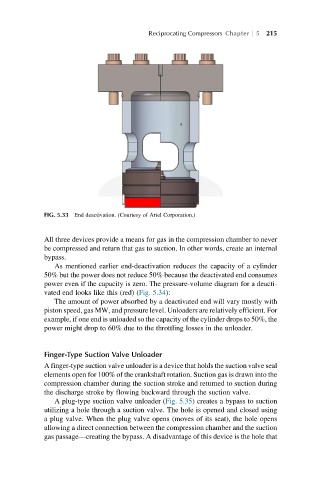

FIG. 5.33 End deactivation. (Courtesy of Ariel Corporation.)

All three devices provide a means for gas in the compression chamber to never

be compressed and return that gas to suction. In other words, create an internal

bypass.

As mentioned earlier end-deactivation reduces the capacity of a cylinder

50% but the power does not reduce 50% because the deactivated end consumes

power even if the capacity is zero. The pressure-volume diagram for a deacti-

vated end looks like this (red) (Fig. 5.34):

The amount of power absorbed by a deactivated end will vary mostly with

piston speed, gas MW, and pressure level. Unloaders are relatively efficient. For

example, if one end is unloaded so the capacity of the cylinder drops to 50%, the

power might drop to 60% due to the throttling losses in the unloader.

Finger-Type Suction Valve Unloader

A finger-type suction valve unloader is a device that holds the suction valve seal

elements open for 100% of the crankshaft rotation. Suction gas is drawn into the

compression chamber during the suction stroke and returned to suction during

the discharge stroke by flowing backward through the suction valve.

A plug-type suction valve unloader (Fig. 5.35) creates a bypass to suction

utilizing a hole through a suction valve. The hole is opened and closed using

a plug valve. When the plug valve opens (moves of its seat), the hole opens

allowing a direct connection between the compression chamber and the suction

gas passage—creating the bypass. A disadvantage of this device is the hole that