Page 428 - Compression Machinery for Oil and Gas

P. 428

Downstream Chapter 10 407

These compressors do not generally present technical challenges other than

those normally related to trains involving multiple large units.

Subcooling service can be accomplished by two or three casings (horizon-

tally split and/or barrel design). The critical aspect of this service is the low-

temperature material selection requirements.

Typically the material chosen for such low-temperature service is steel with

9% nickel (ASTM A522).

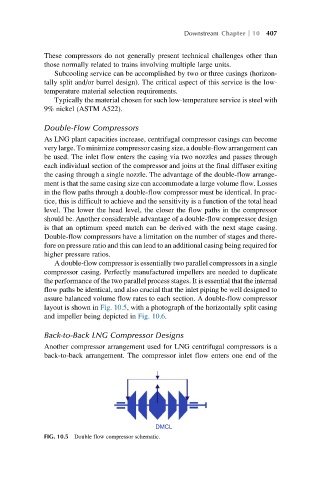

Double-Flow Compressors

As LNG plant capacities increase, centrifugal compressor casings can become

very large. To minimize compressor casing size, a double-flow arrangement can

be used. The inlet flow enters the casing via two nozzles and passes through

each individual section of the compressor and joins at the final diffuser exiting

the casing through a single nozzle. The advantage of the double-flow arrange-

ment is that the same casing size can accommodate a large volume flow. Losses

in the flow paths through a double-flow compressor must be identical. In prac-

tice, this is difficult to achieve and the sensitivity is a function of the total head

level. The lower the head level, the closer the flow paths in the compressor

should be. Another considerable advantage of a double-flow compressor design

is that an optimum speed match can be derived with the next stage casing.

Double-flow compressors have a limitation on the number of stages and there-

fore on pressure ratio and this can lead to an additional casing being required for

higher pressure ratios.

A double-flow compressor is essentially two parallel compressors in a single

compressor casing. Perfectly manufactured impellers are needed to duplicate

the performance of the two parallel process stages. It is essential that the internal

flow paths be identical, and also crucial that the inlet piping be well designed to

assure balanced volume flow rates to each section. A double-flow compressor

layout is shown in Fig. 10.5, with a photograph of the horizontally split casing

and impeller being depicted in Fig. 10.6.

Back-to-Back LNG Compressor Designs

Another compressor arrangement used for LNG centrifugal compressors is a

back-to-back arrangement. The compressor inlet flow enters one end of the

DMCL

FIG. 10.5 Double flow compressor schematic.