Page 99 -

P. 99

Production and Supply Chain Management Information Systems

specifications. Examples of make-to-order items are airplanes and large

industrial equipment.

• Assemble-to-order—Items are produced using a combination of make-to-

stock and make-to-order processes; the final product is assembled for a

specific order from a selection of make-to-stock components. Personal

79

computers are a typical assemble-to-order product.

Fitter’s Manufacturing Process

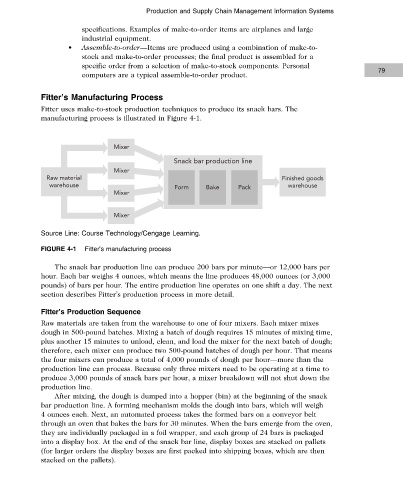

Fitter uses make-to-stock production techniques to produce its snack bars. The

manufacturing process is illustrated in Figure 4-1.

Mixer

Snack bar production line

Mixer

Raw material Finished goods

warehouse Form Bake Pack warehouse

Mixer

Mixer

Source Line: Course Technology/Cengage Learning.

FIGURE 4-1 Fitter’s manufacturing process

The snack bar production line can produce 200 bars per minute—or 12,000 bars per

hour. Each bar weighs 4 ounces, which means the line produces 48,000 ounces (or 3,000

pounds) of bars per hour. The entire production line operates on one shift a day. The next

section describes Fitter’s production process in more detail.

Fitter’s Production Sequence

Raw materials are taken from the warehouse to one of four mixers. Each mixer mixes

dough in 500-pound batches. Mixing a batch of dough requires 15 minutes of mixing time,

plus another 15 minutes to unload, clean, and load the mixer for the next batch of dough;

therefore, each mixer can produce two 500-pound batches of dough per hour. That means

the four mixers can produce a total of 4,000 pounds of dough per hour—more than the

production line can process. Because only three mixers need to be operating at a time to

produce 3,000 pounds of snack bars per hour, a mixer breakdown will not shut down the

production line.

After mixing, the dough is dumped into a hopper (bin) at the beginning of the snack

bar production line. A forming mechanism molds the dough into bars, which will weigh

4 ounces each. Next, an automated process takes the formed bars on a conveyor belt

through an oven that bakes the bars for 30 minutes. When the bars emerge from the oven,

they are individually packaged in a foil wrapper, and each group of 24 bars is packaged

into a display box. At the end of the snack bar line, display boxes are stacked on pallets

(for larger orders the display boxes are first packed into shipping boxes, which are then

stacked on the pallets).

Copyright 2012 Cengage Learning. All Rights Reserved. May not be copied, scanned, or duplicated, in whole or in part. Due to electronic rights, some third party content may be suppressed from the eBook and/or eChapter(s).

Editorial review has deemed that any suppressed content does not materially affect the overall learning experience. Cengage Learning reserves the right to remove additional content at any time if subsequent rights restrictions require it.