Page 102 - Construction Waterproofing Handbook

P. 102

BELOW-GRADE WATERPROOFING 2.65

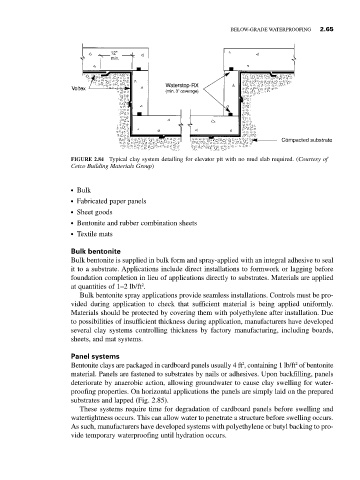

FIGURE 2.84 Typical clay system detailing for elevator pit with no mud slab required. (Courtesy of

Cetco Building Materials Group)

● Bulk

● Fabricated paper panels

● Sheet goods

● Bentonite and rubber combination sheets

● Textile mats

Bulk bentonite

Bulk bentonite is supplied in bulk form and spray-applied with an integral adhesive to seal

it to a substrate. Applications include direct installations to formwork or lagging before

foundation completion in lieu of applications directly to substrates. Materials are applied

2

at quantities of 1–2 lb/ft .

Bulk bentonite spray applications provide seamless installations. Controls must be pro-

vided during application to check that sufficient material is being applied uniformly.

Materials should be protected by covering them with polyethylene after installation. Due

to possibilities of insufficient thickness during application, manufacturers have developed

several clay systems controlling thickness by factory manufacturing, including boards,

sheets, and mat systems.

Panel systems

2

2

Bentonite clays are packaged in cardboard panels usually 4 ft , containing 1 lb/ft of bentonite

material. Panels are fastened to substrates by nails or adhesives. Upon backfilling, panels

deteriorate by anaerobic action, allowing groundwater to cause clay swelling for water-

proofing properties. On horizontal applications the panels are simply laid on the prepared

substrates and lapped (Fig. 2.85).

These systems require time for degradation of cardboard panels before swelling and

watertightness occurs. This can allow water to penetrate a structure before swelling occurs.

As such, manufacturers have developed systems with polyethylene or butyl backing to pro-

vide temporary waterproofing until hydration occurs.