Page 308 - Construction Waterproofing Handbook

P. 308

6.12 CHAPTER SIX

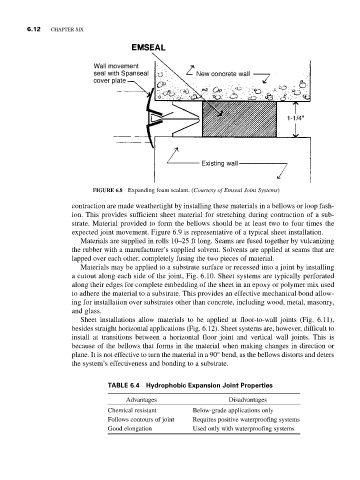

FIGURE 6.8 Expanding foam sealant. (Courtesy of Emseal Joint Systems)

contraction are made weathertight by installing these materials in a bellows or loop fash-

ion. This provides sufficient sheet material for stretching during contraction of a sub-

strate. Material provided to form the bellows should be at least two to four times the

expected joint movement. Figure 6.9 is representative of a typical sheet installation.

Materials are supplied in rolls 10–25 ft long. Seams are fused together by vulcanizing

the rubber with a manufacturer’s supplied solvent. Solvents are applied at seams that are

lapped over each other, completely fusing the two pieces of material.

Materials may be applied to a substrate surface or recessed into a joint by installing

a cutout along each side of the joint, Fig. 6.10. Sheet systems are typically perforated

along their edges for complete embedding of the sheet in an epoxy or polymer mix used

to adhere the material to a substrate. This provides an effective mechanical bond allow-

ing for installation over substrates other than concrete, including wood, metal, masonry,

and glass.

Sheet installations allow materials to be applied at floor-to-wall joints (Fig. 6.11),

besides straight horizontal applications (Fig. 6.12). Sheet systems are, however, difficult to

install at transitions between a horizontal floor joint and vertical wall joints. This is

because of the bellows that forms in the material when making changes in direction or

plane. It is not effective to turn the material in a 90° bend, as the bellows distorts and deters

the system’s effectiveness and bonding to a substrate.

TABLE 6.4 Hydrophobic Expansion Joint Properties

Advantages Disadvantages

Chemical resistant Below-grade applications only

Follows contours of joint Requires positive waterproofing systems

Good elongation Used only with waterproofing systems