Page 312 - Construction Waterproofing Handbook

P. 312

6.16 CHAPTER SIX

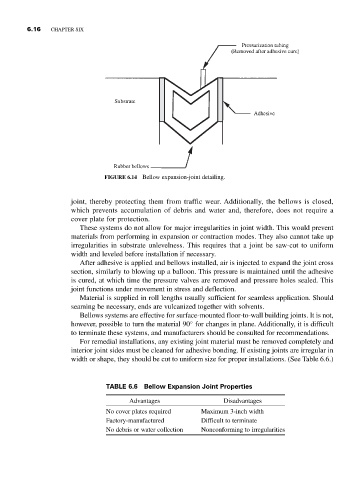

FIGURE 6.14 Bellow expansion-joint detailing.

joint, thereby protecting them from traffic wear. Additionally, the bellows is closed,

which prevents accumulation of debris and water and, therefore, does not require a

cover plate for protection.

These systems do not allow for major irregularities in joint width. This would prevent

materials from performing in expansion or contraction modes. They also cannot take up

irregularities in substrate unlevelness. This requires that a joint be saw-cut to uniform

width and leveled before installation if necessary.

After adhesive is applied and bellows installed, air is injected to expand the joint cross

section, similarly to blowing up a balloon. This pressure is maintained until the adhesive

is cured, at which time the pressure valves are removed and pressure holes sealed. This

joint functions under movement in stress and deflection.

Material is supplied in roll lengths usually sufficient for seamless application. Should

seaming be necessary, ends are vulcanized together with solvents.

Bellows systems are effective for surface-mounted floor-to-wall building joints. It is not,

however, possible to turn the material 90° for changes in plane. Additionally, it is difficult

to terminate these systems, and manufacturers should be consulted for recommendations.

For remedial installations, any existing joint material must be removed completely and

interior joint sides must be cleaned for adhesive bonding. If existing joints are irregular in

width or shape, they should be cut to uniform size for proper installations. (See Table 6.6.)

TABLE 6.6 Bellow Expansion Joint Properties

Advantages Disadvantages

No cover plates required Maximum 3-inch width

Factory-manufactured Difficult to terminate

No debris or water collection Nonconforming to irregularities