Page 314 - Construction Waterproofing Handbook

P. 314

6.18 CHAPTER SIX

TABLE 6.7 Preformed Rubber Expansion Joint Properties

Advantages Disadvantages

Factory manufactured Cost

High-impact strength Difficult transitions

Chemical resistant Limited remedial applications

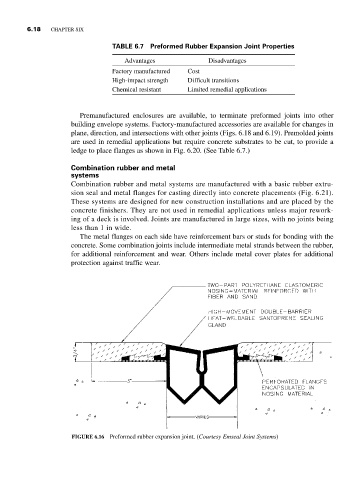

Premanufactured enclosures are available, to terminate preformed joints into other

building envelope systems. Factory-manufactured accessories are available for changes in

plane, direction, and intersections with other joints (Figs. 6.18 and 6.19). Premolded joints

are used in remedial applications but require concrete substrates to be cut, to provide a

ledge to place flanges as shown in Fig. 6.20. (See Table 6.7.)

Combination rubber and metal

systems

Combination rubber and metal systems are manufactured with a basic rubber extru-

sion seal and metal flanges for casting directly into concrete placements (Fig. 6.21).

These systems are designed for new construction installations and are placed by the

concrete finishers. They are not used in remedial applications unless major rework-

ing of a deck is involved. Joints are manufactured in large sizes, with no joints being

less than 1 in wide.

The metal flanges on each side have reinforcement bars or studs for bonding with the

concrete. Some combination joints include intermediate metal strands between the rubber,

for additional reinforcement and wear. Others include metal cover plates for additional

protection against traffic wear.

FIGURE 6.16 Preformed rubber expansion joint. (Courtesy Emseal Joint Systems)