Page 315 - Construction Waterproofing Handbook

P. 315

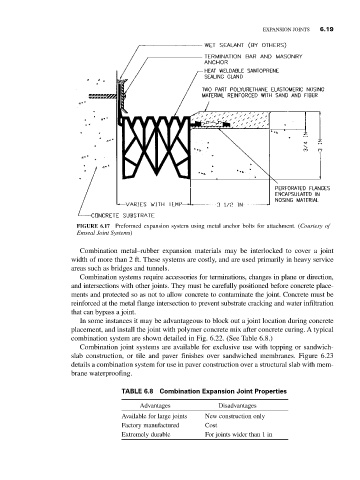

EXPANSION JOINTS 6.19

FIGURE 6.17 Preformed expansion system using metal anchor bolts for attachment. (Courtesy of

Emseal Joint Systems)

Combination metal–rubber expansion materials may be interlocked to cover a joint

width of more than 2 ft. These systems are costly, and are used primarily in heavy service

areas such as bridges and tunnels.

Combination systems require accessories for terminations, changes in plane or direction,

and intersections with other joints. They must be carefully positioned before concrete place-

ments and protected so as not to allow concrete to contaminate the joint. Concrete must be

reinforced at the metal flange intersection to prevent substrate cracking and water infiltration

that can bypass a joint.

In some instances it may be advantageous to block out a joint location during concrete

placement, and install the joint with polymer concrete mix after concrete curing. A typical

combination system are shown detailed in Fig. 6.22. (See Table 6.8.)

Combination joint systems are available for exclusive use with topping or sandwich-

slab construction, or tile and paver finishes over sandwiched membranes. Figure 6.23

details a combination system for use in paver construction over a structural slab with mem-

brane waterproofing.

TABLE 6.8 Combination Expansion Joint Properties

Advantages Disadvantages

Available for large joints New construction only

Factory manufactured Cost

Extremely durable For joints wider than 1 in