Page 321 - Construction Waterproofing Handbook

P. 321

EXPANSION JOINTS 6.23

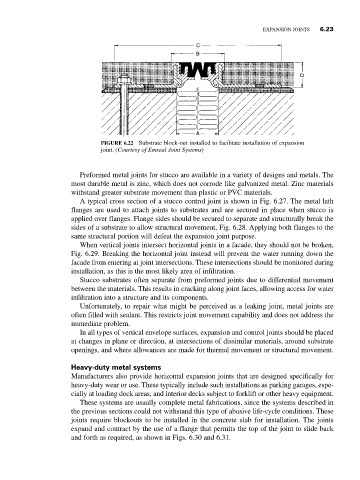

FIGURE 6.22 Substrate block-out installed to facilitate installation of expansion

joint. (Courtesy of Emseal Joint Systems)

Preformed metal joints for stucco are available in a variety of designs and metals. The

most durable metal is zinc, which does not corrode like galvanized metal. Zinc materials

withstand greater substrate movement than plastic or PVC materials.

A typical cross section of a stucco control joint is shown in Fig. 6.27. The metal lath

flanges are used to attach joints to substrates and are secured in place when stucco is

applied over flanges. Flange sides should be secured to separate and structurally break the

sides of a substrate to allow structural movement, Fig. 6.28. Applying both flanges to the

same structural portion will defeat the expansion joint purpose.

When vertical joints intersect horizontal joints in a facade, they should not be broken,

Fig. 6.29. Breaking the horizontal joint instead will prevent the water running down the

facade from entering at joint intersections. These intersections should be monitored during

installation, as this is the most likely area of infiltration.

Stucco substrates often separate from preformed joints due to differential movement

between the materials. This results in cracking along joint faces, allowing access for water

infiltration into a structure and its components.

Unfortunately, to repair what might be perceived as a leaking joint, metal joints are

often filled with sealant. This restricts joint movement capability and does not address the

immediate problem.

In all types of vertical envelope surfaces, expansion and control joints should be placed

at changes in plane or direction, at intersections of dissimilar materials, around substrate

openings, and where allowances are made for thermal movement or structural movement.

Heavy-duty metal systems

Manufacturers also provide horizontal expansion joints that are designed specifically for

heavy-duty wear or use. These typically include such installations as parking garages, espe-

cially at loading dock areas, and interior decks subject to forklift or other heavy equipment.

These systems are usually complete metal fabrications, since the systems described in

the previous sections could not withstand this type of abusive life-cycle conditions. These

joints require blockouts to be installed in the concrete slab for installation. The joints

expand and contract by the use of a flange that permits the top of the joint to slide back

and forth as required, as shown in Figs. 6.30 and 6.31.