Page 335 - Construction Waterproofing Handbook

P. 335

ADMIXTURES 7.3

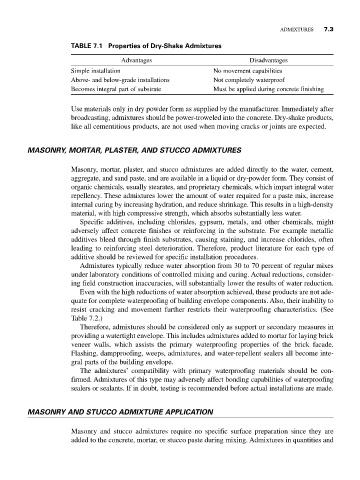

TABLE 7.1 Properties of Dry-Shake Admixtures

Advantages Disadvantages

Simple installation No movement capabilities

Above- and below-grade installations Not completely waterproof

Becomes integral part of substrate Must be applied during concrete finishing

Use materials only in dry powder form as supplied by the manufacturer. Immediately after

broadcasting, admixtures should be power-troweled into the concrete. Dry-shake products,

like all cementitious products, are not used when moving cracks or joints are expected.

MASONRY, MORTAR, PLASTER, AND STUCCO ADMIXTURES

Masonry, mortar, plaster, and stucco admixtures are added directly to the water, cement,

aggregate, and sand paste, and are available in a liquid or dry-powder form. They consist of

organic chemicals, usually stearates, and proprietary chemicals, which impart integral water

repellency. These admixtures lower the amount of water required for a paste mix, increase

internal curing by increasing hydration, and reduce shrinkage. This results in a high-density

material, with high compressive strength, which absorbs substantially less water.

Specific additives, including chlorides, gypsum, metals, and other chemicals, might

adversely affect concrete finishes or reinforcing in the substrate. For example metallic

additives bleed through finish substrates, causing staining, and increase chlorides, often

leading to reinforcing steel deterioration. Therefore, product literature for each type of

additive should be reviewed for specific installation procedures.

Admixtures typically reduce water absorption from 30 to 70 percent of regular mixes

under laboratory conditions of controlled mixing and curing. Actual reductions, consider-

ing field construction inaccuracies, will substantially lower the results of water reduction.

Even with the high reductions of water absorption achieved, these products are not ade-

quate for complete waterproofing of building envelope components. Also, their inability to

resist cracking and movement further restricts their waterproofing characteristics. (See

Table 7.2.)

Therefore, admixtures should be considered only as support or secondary measures in

providing a watertight envelope. This includes admixtures added to mortar for laying brick

veneer walls, which assists the primary waterproofing properties of the brick facade.

Flashing, dampproofing, weeps, admixtures, and water-repellent sealers all become inte-

gral parts of the building envelope.

The admixtures’ compatibility with primary waterproofing materials should be con-

firmed. Admixtures of this type may adversely affect bonding capabilities of waterproofing

sealers or sealants. If in doubt, testing is recommended before actual installations are made.

MASONRY AND STUCCO ADMIXTURE APPLICATION

Masonry and stucco admixtures require no specific surface preparation since they are

added to the concrete, mortar, or stucco paste during mixing. Admixtures in quantities and