Page 337 - Construction Waterproofing Handbook

P. 337

ADMIXTURES 7.5

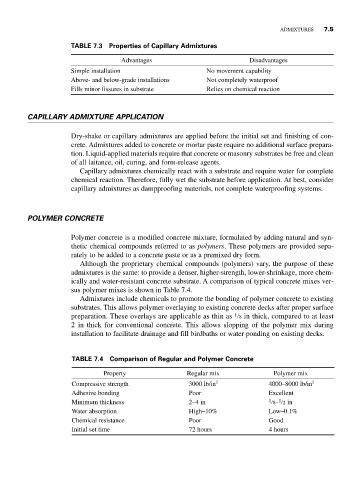

TABLE 7.3 Properties of Capillary Admixtures

Advantages Disadvantages

Simple installation No movement capability

Above- and below-grade installations Not completely waterproof

Fills minor fissures in substrate Relies on chemical reaction

CAPILLARY ADMIXTURE APPLICATION

Dry-shake or capillary admixtures are applied before the initial set and finishing of con-

crete. Admixtures added to concrete or mortar paste require no additional surface prepara-

tion. Liquid-applied materials require that concrete or masonry substrates be free and clean

of all laitance, oil, curing, and form-release agents.

Capillary admixtures chemically react with a substrate and require water for complete

chemical reaction. Therefore, fully wet the substrate before application. At best, consider

capillary admixtures as dampproofing materials, not complete waterproofing systems.

POLYMER CONCRETE

Polymer concrete is a modified concrete mixture, formulated by adding natural and syn-

thetic chemical compounds referred to as polymers. These polymers are provided sepa-

rately to be added to a concrete paste or as a premixed dry form.

Although the proprietary chemical compounds (polymers) vary, the purpose of these

admixtures is the same: to provide a denser, higher-strength, lower-shrinkage, more chem-

ically and water-resistant concrete substrate. A comparison of typical concrete mixes ver-

sus polymer mixes is shown in Table 7.4.

Admixtures include chemicals to promote the bonding of polymer concrete to existing

substrates. This allows polymer overlaying to existing concrete decks after proper surface

1

preparation. These overlays are applicable as thin as 8 in thick, compared to at least

2 in thick for conventional concrete. This allows slopping of the polymer mix during

installation to facilitate drainage and fill birdbaths or water ponding on existing decks.

TABLE 7.4 Comparison of Regular and Polymer Concrete

Property Regular mix Polymer mix

Compressive strength 3000 lb/in 2 4000–8000 lb/in 2

Adhesive bonding Poor Excellent

1

Minimum thickness 2–4 in 1 8– 2 in

Water absorption High–10% Low–0.1%

Chemical resistance Poor Good

Initial set time 72 hours 4 hours