Page 55 - Construction Waterproofing Handbook

P. 55

BELOW-GRADE WATERPROOFING 2.19

Testing of failed joints usually reveals that failures were either the cause of improperly

positioned material, Fig. 2.28, (folded over during concrete placement) or where directional

changes occurred in structure that the waterstop did not conform to. Whenever heat welding

is used, the material is adversely affected at this point and its properties are not equal to the

original material. Therefore it is recommended that whenever major directional changes are

designed into a structure, the contractor should secure prefabricated fittings. Waterstop man-

ufacturers will usually provide a variety of premolded splice pieces for directional changes,

as shown in Fig. 2.29. Also, most manufacturers will offer to custom-make the required

splices to ensure the successful applications with their material.

At all penetrations in below-grade slabs or walls, waterstop should also be installed contin-

uously around the penetration to protect against water penetration. Figure 2.30 details the use

of waterstop installed continuously around a structural steel column that penetrates the concrete

slab over the foundation.

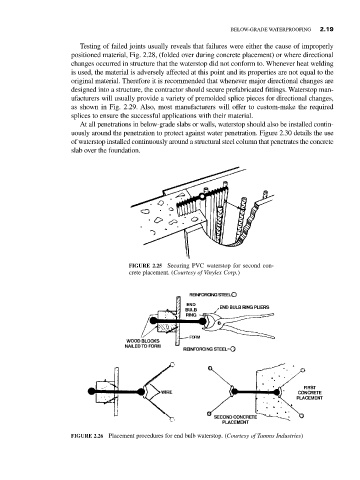

FIGURE 2.25 Securing PVC waterstop for second con-

crete placement. (Courtesy of Vinylex Corp.)

FIGURE 2.26 Placement procedures for end bulb waterstop. (Courtesy of Tamms Industries)