Page 178 - Corrosion Engineering Principles and Practice

P. 178

152 C h a p t e r 6 R e c o g n i z i n g t h e F o r m s o f C o r r o s i o n 153

ultrasonic equipment has been enhanced greatly by combining the

basic electronics with computers. However, many instruments still in

use today are for single-point thickness measurements, which do not

provide the capability of the more sophisticated systems.

Rugged instruments based on portable computers are now

available from many vendors. These systems, complete with motor-

driven robotic devices to manipulate the transducer(s), have created

the ability to measure wall thickness of corroded components at tens

2

of thousands of points over 0.1 m , which can be converted into mass

loss and pitting rates. This capability, coupled with increased precision

of field measurements achievable with computer-controlled systems,

has made these automated ultrasonic systems well suited for online

corrosion monitoring [4].

Developments are now being made with individual transducers

or transducer arrays that are left in place to provide continuous

monitoring. Permanently attached transducers improve accuracy

by removing errors in relocating a transducer to exactly the same

point with exactly the same couplant thickness. With proper

transducer selection, equipment setup, and controlled temperature

conditions, the accuracy of controlled ultrasonic inspection can

exceed ±0.025 mm in a laboratory setting. Field inspections are

typically to within ±0.1 mm.

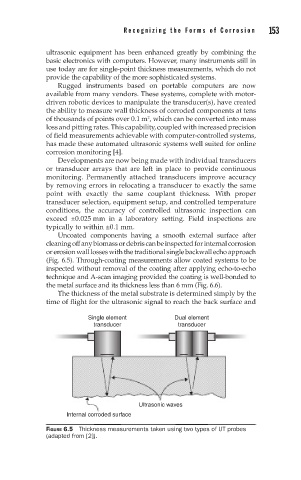

Uncoated components having a smooth external surface after

cleaning off any biomass or debris can be inspected for internal corrosion

or erosion wall losses with the traditional single backwall echo approach

(Fig. 6.5). Through-coating measurements allow coated systems to be

inspected without removal of the coating after applying echo-to-echo

technique and A-scan imaging provided the coating is well-bonded to

the metal surface and its thickness less than 6 mm (Fig. 6.6).

The thickness of the metal substrate is determined simply by the

time of flight for the ultrasonic signal to reach the back surface and

Single element Dual element

transducer transducer

Ultrasonic waves

Internal corroded surface

FIGURE 6.5 Thickness measurements taken using two types of UT probes

(adapted from [2]).