Page 179 - Corrosion Engineering Principles and Practice

P. 179

154 C h a p t e r 6 R e c o g n i z i n g t h e F o r m s o f C o r r o s i o n 155

Dual element

transducer

Paint coating

Ultrasonic waves

Internal corroded surface

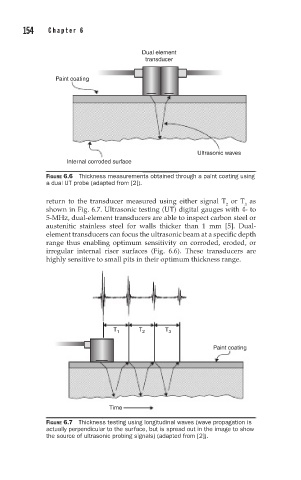

FIGURE 6.6 Thickness measurements obtained through a paint coating using

a dual UT probe (adapted from [2]).

return to the transducer measured using either signal T or T as

3

2

shown in Fig. 6.7. Ultrasonic testing (UT) digital gauges with 4- to

5-MHz, dual-element transducers are able to inspect carbon steel or

austenitic stainless steel for walls thicker than 1 mm [5]. Dual-

element transducers can focus the ultrasonic beam at a specific depth

range thus enabling optimum sensitivity on corroded, eroded, or

irregular internal riser surfaces (Fig. 6.6). These transducers are

highly sensitive to small pits in their optimum thickness range.

T 1 T 2 T 3

Paint coating

Time

FIGURE 6.7 Thickness testing using longitudinal waves (wave propagation is

actually perpendicular to the surface, but is spread out in the image to show

the source of ultrasonic probing signals) (adapted from [2]).