Page 318 - Corrosion Engineering Principles and Practice

P. 318

288 C h a p t e r 8 C o r r o s i o n b y W a t e r 289

Air out

Warm water in

Packing

Air in Air in

Cooled water out

Makeup water

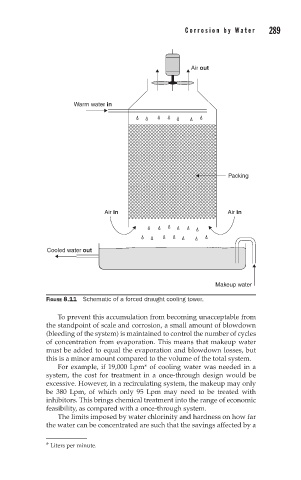

FIGURE 8.11 Schematic of a forced draught cooling tower.

To prevent this accumulation from becoming unacceptable from

the standpoint of scale and corrosion, a small amount of blowdown

(bleeding of the system) is maintained to control the number of cycles

of concentration from evaporation. This means that makeup water

must be added to equal the evaporation and blowdown losses, but

this is a minor amount compared to the volume of the total system.

For example, if 19,000 Lpm* of cooling water was needed in a

system, the cost for treatment in a once-through design would be

excessive. However, in a recirculating system, the makeup may only

be 380 Lpm, of which only 95 Lpm may need to be treated with

inhibitors. This brings chemical treatment into the range of economic

feasibility, as compared with a once-through system.

The limits imposed by water chlorinity and hardness on how far

the water can be concentrated are such that the savings affected by a

* Liters per minute.