Page 358 - Corrosion Engineering Principles and Practice

P. 358

326 C h a p t e r 8 C o r r o s i o n b y W a t e r 327

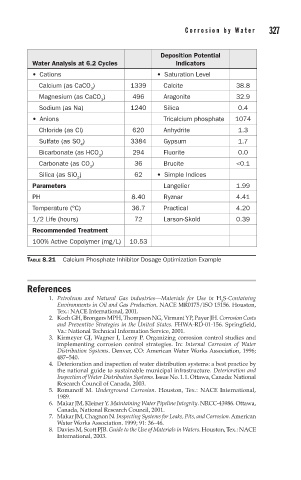

Deposition Potential

Water Analysis at 6.2 Cycles Indicators

• Cations • Saturation Level

Calcium (as CaCO ) 1339 Calcite 38.8

3

Magnesium (as CaCO ) 496 Aragonite 32.9

3

Sodium (as Na) 1240 Silica 0.4

• Anions Tricalcium phosphate 1074

Chloride (as Cl) 620 Anhydrite 1.3

Sulfate (as SO ) 3384 Gypsum 1.7

4

Bicarbonate (as HCO ) 294 Fluorite 0.0

3

Carbonate (as CO ) 36 Brucite <0.1

3

Silica (as SiO ) 62 • Simple Indices

2

Parameters Langelier 1.99

PH 8.40 Ryznar 4.41

Temperature (°C) 36.7 Practical 4.20

1/2 Life (hours) 72 Larson-Skold 0.39

Recommended Treatment

100% Active Copolymer (mg/L) 10.53

TABLE 8.21 Calcium Phosphate Inhibitor Dosage Optimization Example

References

1. Petroleum and Natural Gas industries—Materials for Use in H S-Containing

2

Environments in Oil and Gas Production. NACE MR0175/ISO 15156. Houston,

Tex.: NACE International, 2001.

2. Koch GH, Brongers MPH, Thompson NG, Virmani YP, Payer JH. Corrosion Costs

and Preventive Strategies in the United States. FHWA-RD-01-156. Springfield,

Va.: National Technical Information Service, 2001.

3. Kirmeyer GJ, Wagner I, Leroy P. Organizing corrosion control studies and

implementing corrosion control strategies. In: Internal Corrosion of Water

Distribution Systems. Denver, CO: American Water Works Association, 1996;

487–540.

4. Deterioration and inspection of water distribution systems: a best practice by

the national guide to sustainable municipal infrastructure. Deterioration and

Inspection of Water Distribution Systems. Issue No. 1.1. Ottawa, Canada: National

Research Council of Canada, 2003.

5. Romanoff M. Underground Corrosion. Houston, Tex.: NACE International,

1989.

6. Makar JM, Kleiner Y. Maintaining Water Pipeline Integrity. NRCC-43986. Ottawa,

Canada, National Research Council, 2001.

7. Makar JM, Chagnon N. Inspecting Systems for Leaks, Pits, and Corrosion. American

Water Works Association. 1999; 91: 36–46.

8. Davies M, Scott PJB. Guide to the Use of Materials in Waters. Houston, Tex.: NACE

International, 2003.