Page 536 - Corrosion Engineering Principles and Practice

P. 536

502 C h a p t e r 1 2 C o r r o s i o n a s a R i s k 503

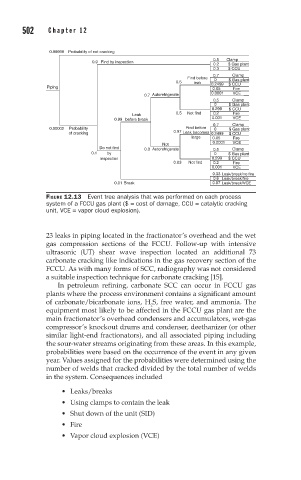

0.99998 Probability of not cracking

0.5 Clamp

0.9 Find by inspection

0.2 $ Gas plant

0.3 $ CCU

0.7 Clamp

Find before 0

0.5 leak 0.2499 $ Gas plant

$ CCU

Piping 0.05 Fire

0.7 Autorefrigerate 0.0001 VCE

0.5 Clamp

0 $ Gas plant

0.299 $ CCU

Leak 0.5 Not find 0.2 Fire

0.99 before break 0.001 VCE

0.7 Clamp

0.00002 Probability Find before 0 $ Gas plant

of cracking 0.97 Leak becomes 0.2499 $ CCU

large 0.05 Fire

Not 0.0001 VCE

Do not find 0.3 Autorefrigerate 0.5 Clamp

0.1 by 0 $ Gas plant

inspection 0.299 $ CCU

0.03 Not find 0.2 Fire

0.001 VCE

0.33 Leak/break/no fire

0.6 Leak/break/fire

0.01 Break 0.07 Leak/break/VCE

FIGURE 12.13 Event tree analysis that was performed on each process

system of a FCCU gas plant ($ = cost of damage, CCU = catalytic cracking

unit, VCE = vapor cloud explosion).

23 leaks in piping located in the fractionator’s overhead and the wet

gas compression sections of the FCCU. Follow-up with intensive

ultrasonic (UT) shear wave inspection located an additional 73

carbonate cracking like indications in the gas recovery section of the

FCCU. As with many forms of SCC, radiography was not considered

a suitable inspection technique for carbonate cracking [15].

In petroleum refining, carbonate SCC can occur in FCCU gas

plants where the process environment contains a significant amount

of carbonate/bicarbonate ions, H S, free water, and ammonia. The

2

equipment most likely to be affected in the FCCU gas plant are the

main fractionator’s overhead condensers and accumulators, wet-gas

compressor’s knockout drums and condenser, deethanizer (or other

similar light-end fractionators), and all associated piping including

the sour-water streams originating from these areas. In this example,

probabilities were based on the occurrence of the event in any given

year. Values assigned for the probabilities were determined using the

number of welds that cracked divided by the total number of welds

in the system. Consequences included

• Leaks/breaks

• Using clamps to contain the leak

• Shut down of the unit (SID)

• Fire

• Vapor cloud explosion (VCE)