Page 711 - Corrosion Engineering Principles and Practice

P. 711

664 C h a p t e r 1 5 H i g h - Te m p e r a t u r e C o r r o s i o n 665

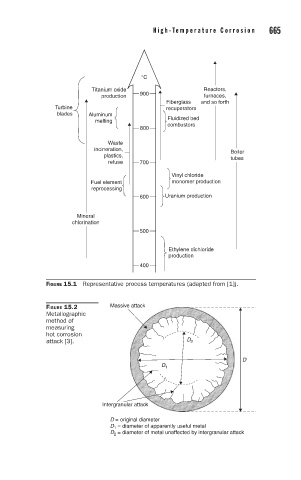

°C

Titanium oxide Reactors,

production 900 furnaces,

Fiberglass and so forth

Turbine recuperators

blades Aluminum

melting Fluidized bed

combustors

800

Waste

incineration, Boiler

plastics, tubes

refuse 700

Vinyl chloride

Fuel element monomer production

reprocessing

600 Uranium production

Mineral

chlorination

500

Ethylene dichloride

production

400

FIGURE 15.1 Representative process temperatures (adapted from [1]).

FIGURE 15.2 Massive attack

Metallographic

method of

measuring

hot corrosion

attack [3]. D 2

D

D 1

Intergranular attack

D = original diameter

D 1 = diameter of apparently useful metal

D 2 = diameter of metal unaffected by intergranular attack