Page 713 - Corrosion Engineering Principles and Practice

P. 713

666 C h a p t e r 1 5 H i g h - Te m p e r a t u r e C o r r o s i o n 667

H /H O ratio 10 –8 10 –6 10 –4 pO 2

2

2

CO/CO ratio 10 –8 10 –6 10 –4 10 –2

2

10 –2

O 0

1

–100 M 10 –2

2CO + O 2 = 2CO 2

M M 2Co + O 2 = 2CoO 1

4Cu + O 2 = 2Cu 2 O 2Fe + O 2 = 2FeO 10 –4

2Ni + O 2 = 2NiO

–200

M

–300 2

M 10

M 10 –6

C + O 2 = CO 2 10 2

∆G 0 = RT ln O 2 (kJ/mole O 2 ) –600 M Si + O 2 = SiO 2 M B 10 4 10 –12

–400

H –500 2Zn + O 2 = 2ZnO B 3 M 10 4 10 –8

C 4 Cr + O 2 = 2 / Cr 2 O 3 2C + O 2 = 2CO –10

/

3

–700

–800 10 6 10 –14

10

4 Al + O 2 = 2 / Al 2 O 2 10 6

3

–900 / B –16

3

M 2Ca + O 2 = 2CaO B 10 8 10

–1000

2Mg + O 2 = 2MgO M M Change of state element oxide 8 10 –18

–1100 Melting point M B M 10

Boiling point

B

10 10 10 –20

–1200

0 200 400 600 800 1000 1200 1400 1600 1800 2000 2200 2400

Temperature(°C) –22

H /H O ratio 10 14 10 12 10 10 10

2

2

0 K CO/CO ratio 10 12

2

10 –50 10 –30 10 –24

pO

2

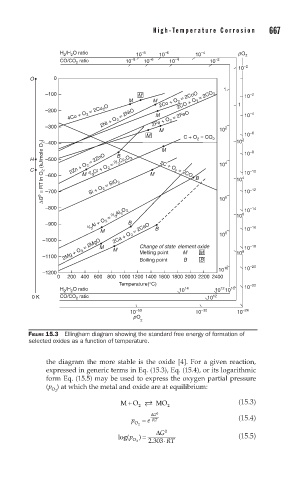

FIGURE 15.3 Ellingham diagram showing the standard free energy of formation of

selected oxides as a function of temperature.

the diagram the more stable is the oxide [4]. For a given reaction,

expressed in generic terms in Eq. (15.3), Eq. (15.4), or its logarithmic

form Eq. (15.5) may be used to express the oxygen partial pressure

(p ) at which the metal and oxide are at equilibrium:

O 2

M O MO (15.3)

+

2

2

G

∆

0

p = e RT (15.4)

O 2

log(p ) = ∆ G 0 (15.5)

O 2 . 2 303⋅ RT