Page 22 - Coulson Richardson's Chemical Engineering Vol.6 Chemical Engineering Design 4th Edition

P. 22

The selection process can be considered to go through the following stages:

within the external constraints.

Possible designs (credible) INTRODUCTION TO DESIGN 5

Plausible designs (feasible) within the internal constraints.

Probable designs likely candidates.

Best design (optimum) judged the best solution to the problem.

The selection process will become more detailed and more refined as the design progresses

from the area of possible to the area of probable solutions. In the early stages a coarse

screening based on common sense, engineering judgement, and rough costings will usually

suffice. For example, it would not take many minutes to narrow down the choice of raw

materials for the manufacture of ammonia from the possible candidates of, say, wood,

peat, coal, natural gas, and oil, to a choice of between gas and oil, but a more detailed

study would be needed to choose between oil and gas. To select the best design from the

probable designs, detailed design work and costing will usually be necessary. However,

where the performance of candidate designs is likely to be close the cost of this further

refinement, in time and money, may not be worthwhile, particularly as there will usually

be some uncertainty in the accuracy of the estimates.

The mathematical techniques that have been developed to assist in the optimisation of

designs, and plant performance, are discussed briefly in Section 1.10.

Rudd and Watson (1968) and Wells (1973) describe formal techniques for the prelim-

inary screening of alternative designs.

1.3. THE ANATOMY OF A CHEMICAL MANUFACTURING

PROCESS

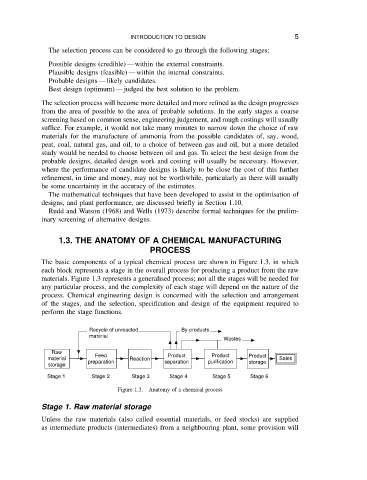

The basic components of a typical chemical process are shown in Figure 1.3, in which

each block represents a stage in the overall process for producing a product from the raw

materials. Figure 1.3 represents a generalised process; not all the stages will be needed for

any particular process, and the complexity of each stage will depend on the nature of the

process. Chemical engineering design is concerned with the selection and arrangement

of the stages, and the selection, specification and design of the equipment required to

perform the stage functions.

Recycle of unreacted By-products

material

Wastes

Raw Feed Product Product

material preparation Reaction separation purification Product Sales

storage storage

Stage 1 Stage 2 Stage 3 Stage 4 Stage 5 Stage 6

Figure 1.3. Anatomy of a chemical process

Stage 1. Raw material storage

Unless the raw materials (also called essential materials, or feed stocks) are supplied

as intermediate products (intermediates) from a neighbouring plant, some provision will