Page 165 - Design for Environment A Guide to Sustainable Product Development

P. 165

144 Cha pte r Ei g h t

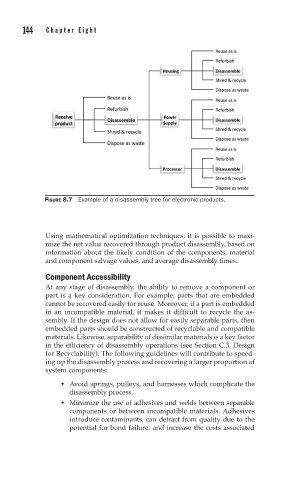

FIGURE 8.7 Example of a disassembly tree for electronic products.

Using mathematical optimization techniques, it is possible to maxi-

mize the net value recovered through product disassembly, based on

information about the likely condition of the components, material

and component salvage values, and average disassembly times.

Component Accessibility

At any stage of disassembly, the ability to remove a component or

part is a key consideration. For example, parts that are embedded

cannot be recovered easily for reuse. Moreover, if a part is embedded

in an incompatible material, it makes it difficult to recycle the as -

sembly. If the design does not allow for easily separable parts, then

embedded parts should be constructed of recyclable and compatible

materials. Likewise, separability of dissimilar materials is a key factor

in the efficiency of disassembly operations (see Section C.3, Design

for Recyclability). The following guidelines will contribute to speed-

ing up the disassembly process and recovering a larger proportion of

system components:

• Avoid springs, pulleys, and harnesses which complicate the

disassembly process.

• Minimize the use of adhesives and welds between separable

components or between incompatible materials. Adhesives

introduce contaminants, can detract from quality due to the

potential for bond failure, and increase the costs associated