Page 181 - Design for Environment A Guide to Sustainable Product Development

P. 181

160 Cha pte r Ei g h t

Advanced Resource Recovery

Resource Cascading

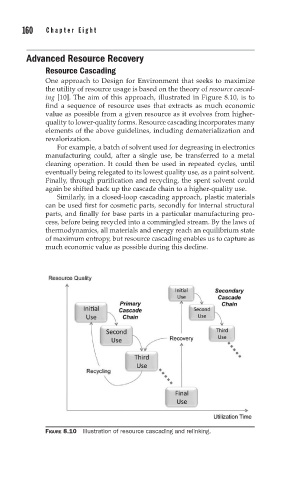

One approach to Design for Environment that seeks to maximize

the utility of resource usage is based on the theory of resource cascad-

ing [10]. The aim of this approach, illustrated in Figure 8.10, is to

find a sequence of resource uses that extracts as much economic

value as possible from a given resource as it evolves from higher-

quality to lower-quality forms. Resource cascading incorporates many

elements of the above guidelines, including dematerialization and

revalorization.

For example, a batch of solvent used for degreasing in electronics

manufacturing could, after a single use, be transferred to a metal

cleaning operation. It could then be used in repeated cycles, until

eventually being relegated to its lowest quality use, as a paint solvent.

Finally, through purification and recycling, the spent solvent could

again be shifted back up the cascade chain to a higher-quality use.

Similarly, in a closed-loop cascading approach, plastic materials

can be used first for cosmetic parts, secondly for internal structural

parts, and finally for base parts in a particular manufacturing pro-

cess, before being recycled into a commingled stream. By the laws of

thermodynamics, all materials and energy reach an equilibrium state

of maximum entropy, but resource cascading enables us to capture as

much economic value as possible during this decline.

FIGURE 8.10 Illustration of resource cascading and relinking.