Page 184 - Design for Environment A Guide to Sustainable Product Development

P. 184

Design Rules and Guidelines 163

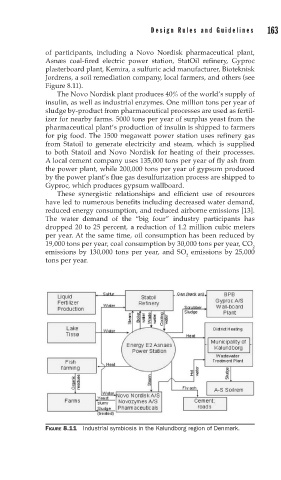

of participants, including a Novo Nordisk pharmaceutical plant,

Asnæs coal-fired electric power station, StatOil refinery, Gyproc

plasterboard plant, Kemira, a sulfuric acid manufacturer, Bioteknisk

Jordrens, a soil remediation company, local farmers, and others (see

Figure 8.11).

The Novo Nordisk plant produces 40% of the world’s supply of

insulin, as well as industrial enzymes. One million tons per year of

sludge by-product from pharmaceutical processes are used as fertil-

izer for nearby farms. 5000 tons per year of surplus yeast from the

pharmaceutical plant’s production of insulin is shipped to farmers

for pig food. The 1500 megawatt power station uses refinery gas

from Statoil to generate electricity and steam, which is supplied

to both Statoil and Novo Nordisk for heating of their processes.

A local cement company uses 135,000 tons per year of fly ash from

the power plant, while 200,000 tons per year of gypsum produced

by the power plant’s flue gas desulfurization process are shipped to

Gyproc, which produces gypsum wallboard.

These synergistic relationships and efficient use of resources

have led to numerous benefits including decreased water demand,

reduced energy consumption, and reduced airborne emissions [13].

The water demand of the “big four” industry participants has

dropped 20 to 25 percent, a reduction of 1.2 million cubic meters

per year. At the same time, oil consumption has been reduced by

19,000 tons per year, coal consumption by 30,000 tons per year, CO

2

emissions by 130,000 tons per year, and SO emissions by 25,000

2

tons per year.

FIGURE 8.11 Industrial symbiosis in the Kalundborg region of Denmark.