Page 114 - Design for Six Sigma a Roadmap for Product Development

P. 114

Product Development Process and Design for Six Sigma 89

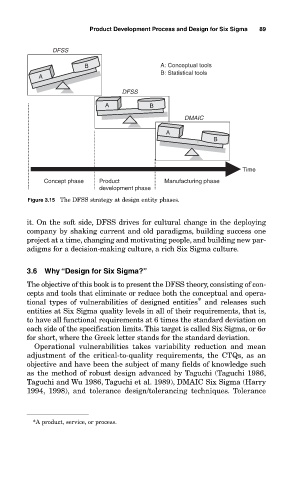

DFSS

B A: Conceptual tools

B: Statistical tools

A

DFSS

A B

DMAIC

A

B

Time

Concept phase Product Manufacturing phase

development phase

Figure 3.15 The DFSS strategy at design entity phases.

it. On the soft side, DFSS drives for cultural change in the deploying

company by shaking current and old paradigms, building success one

project at a time, changing and motivating people, and building new par-

adigms for a decision-making culture, a rich Six Sigma culture.

3.6 Why “Design for Six Sigma?”

The objective of this book is to present the DFSS theory, consisting of con-

cepts and tools that eliminate or reduce both the conceptual and opera-

*

tional types of vulnerabilities of designed entities and releases such

entities at Six Sigma quality levels in all of their requirements, that is,

to have all functional requirements at 6 times the standard deviation on

each side of the specification limits. This target is called Six Sigma, or 6

for short, where the Greek letter stands for the standard deviation.

Operational vulnerabilities takes variability reduction and mean

adjustment of the critical-to-quality requirements, the CTQs, as an

objective and have been the subject of many fields of knowledge such

as the method of robust design advanced by Taguchi (Taguchi 1986,

Taguchi and Wu 1986, Taguchi et al. 1989), DMAIC Six Sigma (Harry

1994, 1998), and tolerance design/tolerancing techniques. Tolerance

*A product, service, or process.