Page 116 - Design for Six Sigma a Roadmap for Product Development

P. 116

Product Development Process and Design for Six Sigma 91

Cost

Cost vs. Impact

Potential is negative

Potential is positive (Impact < Cost)

(Impact > Cost)

Impact

Time

Design Produce/build Deliver Service support

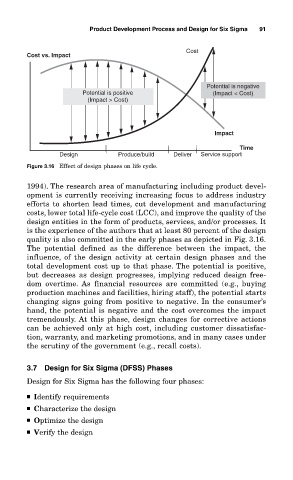

Figure 3.16 Effect of design phases on life cycle.

1994). The research area of manufacturing including product devel-

opment is currently receiving increasing focus to address industry

efforts to shorten lead times, cut development and manufacturing

costs, lower total life-cycle cost (LCC), and improve the quality of the

design entities in the form of products, services, and/or processes. It

is the experience of the authors that at least 80 percent of the design

quality is also committed in the early phases as depicted in Fig. 3.16.

The potential defined as the difference between the impact, the

influence, of the design activity at certain design phases and the

total development cost up to that phase. The potential is positive,

but decreases as design progresses, implying reduced design free-

dom overtime. As financial resources are committed (e.g., buying

production machines and facilities, hiring staff), the potential starts

changing signs going from positive to negative. In the consumer’s

hand, the potential is negative and the cost overcomes the impact

tremendously. At this phase, design changes for corrective actions

can be achieved only at high cost, including customer dissatisfac-

tion, warranty, and marketing promotions, and in many cases under

the scrutiny of the government (e.g., recall costs).

3.7 Design for Six Sigma (DFSS) Phases

Design for Six Sigma has the following four phases:

■ Identify requirements

■ Characterize the design

■ Optimize the design

■ Verify the design