Page 290 - Design for Six Sigma a Roadmap for Product Development

P. 290

260 Chapter Eight

4. Reorder and categorize design matrices at all levels as coupled,

decoupled, or uncoupled.

5. Maintain independence of FRs at all levels of physical structure by

employing the methods presented in this section.

6. Repeat steps 1 to 5 in the process mapping (the mapping from DPs

to PVs).

8.5.4 The decoupling phase

(DFSS algorithm 6.2)

This example is a continuation to Fig. 8.10 of Sec. 8.4.3, where the

mapping of x 1 “displacement mechanism” is depicted.

For sealing device 1, the rotor clearance to the chamber depicted in

Fig. 8.14 will be used as a decoupling example. The zigzagging process

up to the pump is summarized in Fig. 8.15. This device is selected in

this example because sealing devices within the pump are not robust,

resulting in low pump efficiency. Without the DFSS process, the pump

manufacturer will resort to improving the robustness of the seal

through an empirical experiment, an operational vulnerability

improvement phase. This is depicted in Fig. 8.16. This may not be suf-

ficient because the conceptual vulnerability of the seal is a coupled

design. Without resolving the coupling, the best that can be done is a

trade-off between the FR, y 1 “minimize leak from high pressure to

low pressure chamber” and the FR, y 2 “lubricate running surfaces of

the chamber,” since both are delivered by one design parameter x 1.3.1

“the tolerance between the vane and the rotor.” The coupling occurs

because the seal device 1 system is charged with two FRs and one

design parameter; that is, the number of FRs (m 2) is greater than

the number of design parameters (p 1). Clearly, another design para-

meter, say, x 1.3.2 , needs to be introduced to resolve the coupling.

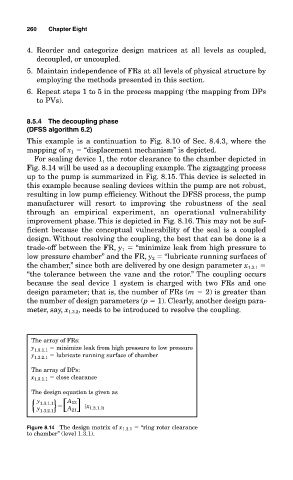

The array of FRs:

y minimize leak from high pressure to low pressure

1.3.1.1

y lubricate running surface of chamber

1.3.2.1

The array of DPs:

x 1.3.1.1 close clearance

The design equation is given as

y

1.3.1.1 A 12

{ y 1.3.2.1 } [ ]A 21 {x 1.3.1.1}

Figure 8.14 The design matrix of x 1.3.1 “ring rotor clearance

to chamber” (level 1.3.1).