Page 466 - Design for Six Sigma for Service (Six SIGMA Operational Methods)

P. 466

424 Chapter Twelve

• Drum-buffer-rope (DBR) is a production control technique used to

implement the theory of constraints.

• If a system has a bottleneck, its production rate controls the pace of the

system. Its beat drives the system, hence the name drum for this control

point.

• A buffer is placed in front of the bottleneck to protect the bottleneck

from fluctuations and variations in the feeding rate to the bottleneck.

The buffer size is measured in the standard time required for the bot-

tleneck to process all items in the buffer.

• The buffer is connected to the raw material dispatching point via a

feedback loop called the rope. The dispatching point will release only

that amount that will keep the buffer inventory build up.

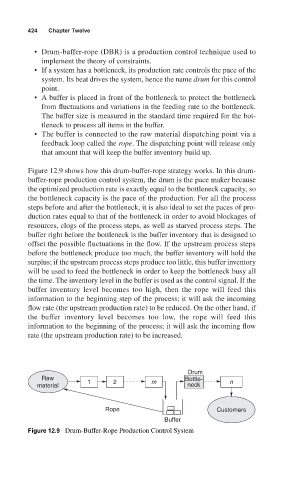

Figure 12.9 shows how this drum-buffer-rope strategy works. In this drum-

buffer-rope production control system, the drum is the pace maker because

the optimized production rate is exactly equal to the bottleneck capacity, so

the bottleneck capacity is the pace of the production. For all the process

steps before and after the bottleneck, it is also ideal to set the paces of pro-

duction rates equal to that of the bottleneck in order to avoid blockages of

resources, clogs of the process steps, as well as starved process steps. The

buffer right before the bottleneck is the buffer inventory that is designed to

offset the possible fluctuations in the flow. If the upstream process steps

before the bottleneck produce too much, the buffer inventory will hold the

surplus; if the upstream process steps produce too little, this buffer inventory

will be used to feed the bottleneck in order to keep the bottleneck busy all

the time. The inventory level in the buffer is used as the control signal. If the

buffer inventory level becomes too high, then the rope will feed this

information to the beginning step of the process; it will ask the incoming

flow rate (the upstream production rate) to be reduced. On the other hand, if

the buffer inventory level becomes too low, the rope will feed this

information to the beginning of the process; it will ask the incoming flow

rate (the upstream production rate) to be increased.

Drum

Raw Bottle-

material 1 2 m neck n

Rope Customers

Buffer

Figure 12.9 Drum-Buffer-Rope Production Control System